AND TRIMMERS

Now it’s time to cut some of the parts that make up the wall, beginning with the window and door headers and the rough sills. Recall from Chapter 3 that headers are needed at window and door openings to transfer the load of the building around these elements to the foundation. This wasn’t always done in old houses, so walls often

|

sagged and doors and windows became hard to open because of all the weight put on them. Frequently, part of a remodeler’s job is to open up old walls and cut in solid headers over every door and window.

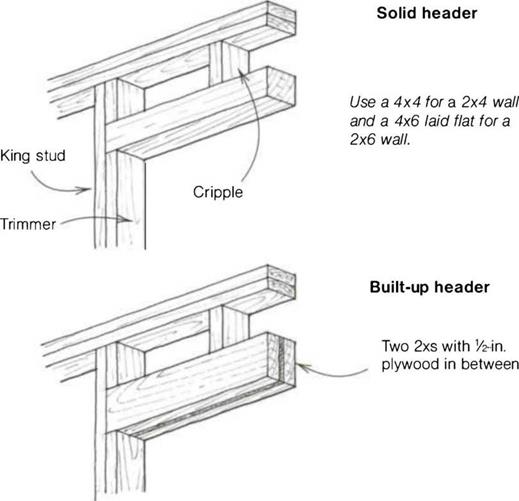

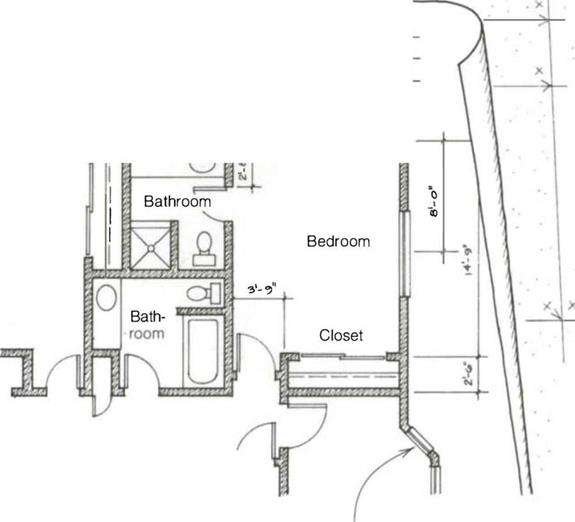

Ordinarily, the distance from the floor to the bottom of the door or window header is б ft. 10 in. Cripple studs (called cripples) are used to fill in the short space between the top of the header and the top plate, or between the bottom of a window opening and the bottom plate. Trimmer studs (called trimmers), nailed to the inside of the studs that border each end of headers, support the headers at the correct height (see the drawing above).

Cutting headers and rough sills

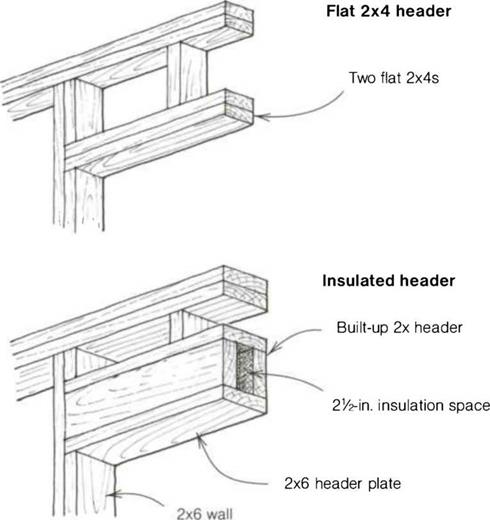

There are different types of headers for different applications. Solid headers (typically a 4×4 or a 4×6) are sometimes used, but more often than not, the headers are built up by sandwiching У2-ІП. plywood between a couple of 2xs. Flat 2x headers can be used for openings in nonbearing walls. Some builders like to put in double flat headers to make sure they have solid nailing for door and window trim. Or you can make a box header that can be filled with insulation to guard against heat loss (see the drawing on p. 108).

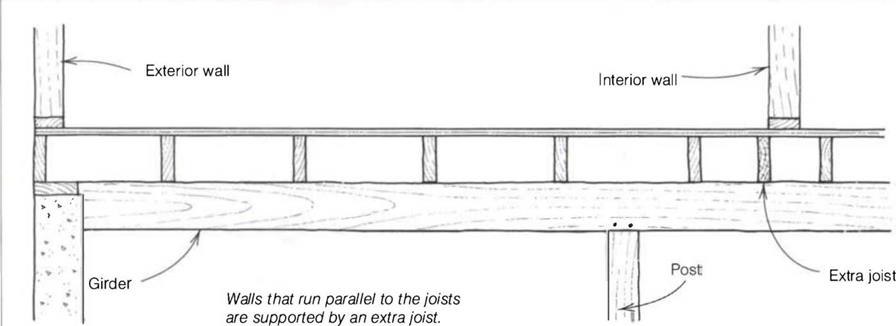

Outside walls are normally considered to be weight-bearing walls. Interior walls can be bearing or nonbearing, depend-

ing on whether they carry weight from above. If you are using manufactured trusses for the roof, all interior walls are usually nonbearing, which makes it possible to use the flat 2x for interior headers. In houses without roof trusses, joists and even roofs might be supported by an interior wall. Such walls are bearing walls and need larger headers to support the weight.

ing on whether they carry weight from above. If you are using manufactured trusses for the roof, all interior walls are usually nonbearing, which makes it possible to use the flat 2x for interior headers. In houses without roof trusses, joists and even roofs might be supported by an interior wall. Such walls are bearing walls and need larger headers to support the weight.

I’m often called on to remove a wall to make a room larger, so it’s important to know about bearing walls. The easiest way to check if a wall is bearing weight is to look in the attic to see whether joists or roof rafters are supported by it. Most walls can be removed, but a bearing wall must be replaced with a beam to support the weight. Of course, another owner may come along later who wants smaller rooms, making work for the next generation of carpenters.

The standard length of a header for doors and windows is 5 in. over the rough-opening size. Thus the header for a З-ft. opening is 41 in. The extra 5 in. leaves 3 in. for a 1 Уг-іп. trimmer on each side, 1Уг in. for а 3/нп. jamb on each side, plus 14 in. to plumb the trimmers. When using prehung doors, cut the headers 51Л in. longer for greater ease in installing the jamb.

Rough-opening sizes for aluminum and vinyl-clad window frames generally are 3 in. wider than the rough-opening size of the window. So, for a 3/6 window, cut the header 45 in. long. The extra 3 in. leaves space for a 1 Уг-іп. trimmer on each side plus enough room to set the window. Window frames are actually У2 in. smaller than their nominal size. So a 3/6 window, for example, is usually 3 ft. 51/2 in. wide. Once set in the rough opening, the frame is nailed on with a 1/4-in. clearance on all sides. This gap is closed in by drywall or wood trim. Rough windowsills are cut to the same length as the corresponding header.

through walls) first. Shorter walls that intersect the through walls are called butt walls. These can be plated once the through walls are in place. Get the long borders of a house in place, and the shorter inside pieces fit together easier.

through walls) first. Shorter walls that intersect the through walls are called butt walls. These can be plated once the through walls are in place. Get the long borders of a house in place, and the shorter inside pieces fit together easier.

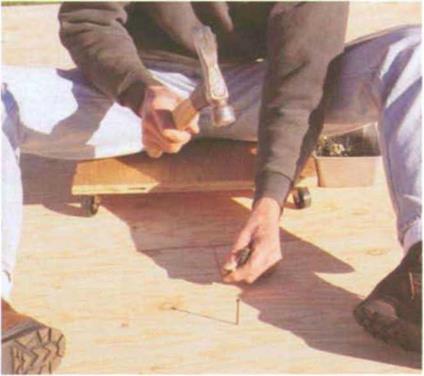

A nail buggy is a good tool when you have to nail subfloor by hand. Better to nail sitting on your bottom than crawling on your knees. Cut a 20-in. circle or square from 3A-in. plywood. Buy three or four good wheels at least 2 in. in diameter and screw them to the bottom of the plywood. Attach a bread pan to the side to hold nails. Now, like an Olympic swimmer doing laps, you can sit on the buggy and push yourself backward as you nail down subfloor. Just don’t roll off the edge of the floor.

A nail buggy is a good tool when you have to nail subfloor by hand. Better to nail sitting on your bottom than crawling on your knees. Cut a 20-in. circle or square from 3A-in. plywood. Buy three or four good wheels at least 2 in. in diameter and screw them to the bottom of the plywood. Attach a bread pan to the side to hold nails. Now, like an Olympic swimmer doing laps, you can sit on the buggy and push yourself backward as you nail down subfloor. Just don’t roll off the edge of the floor.

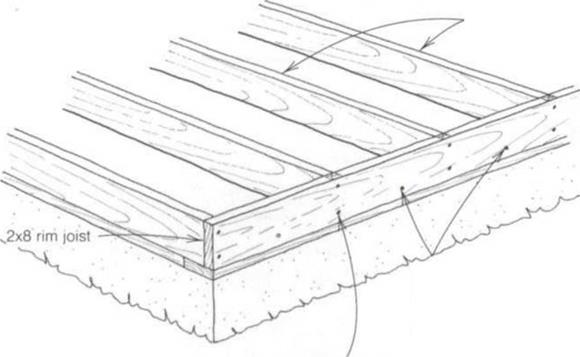

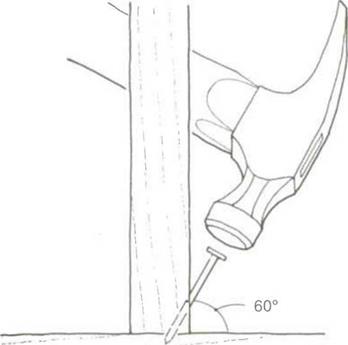

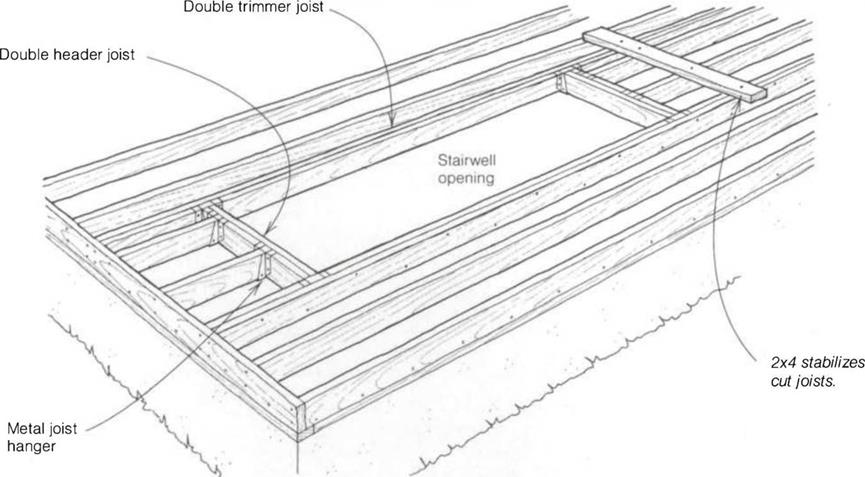

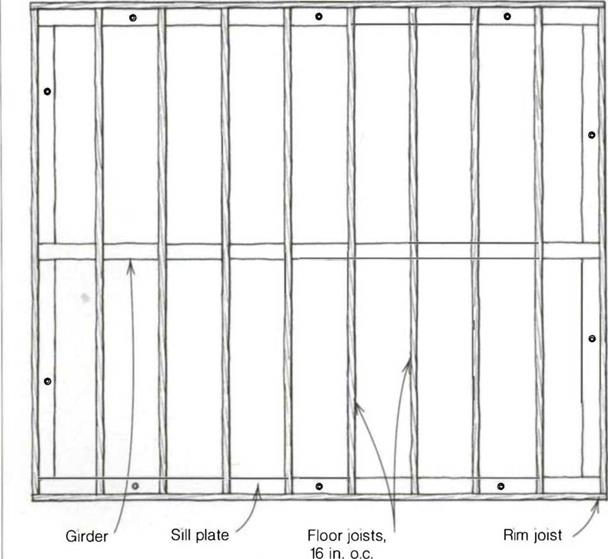

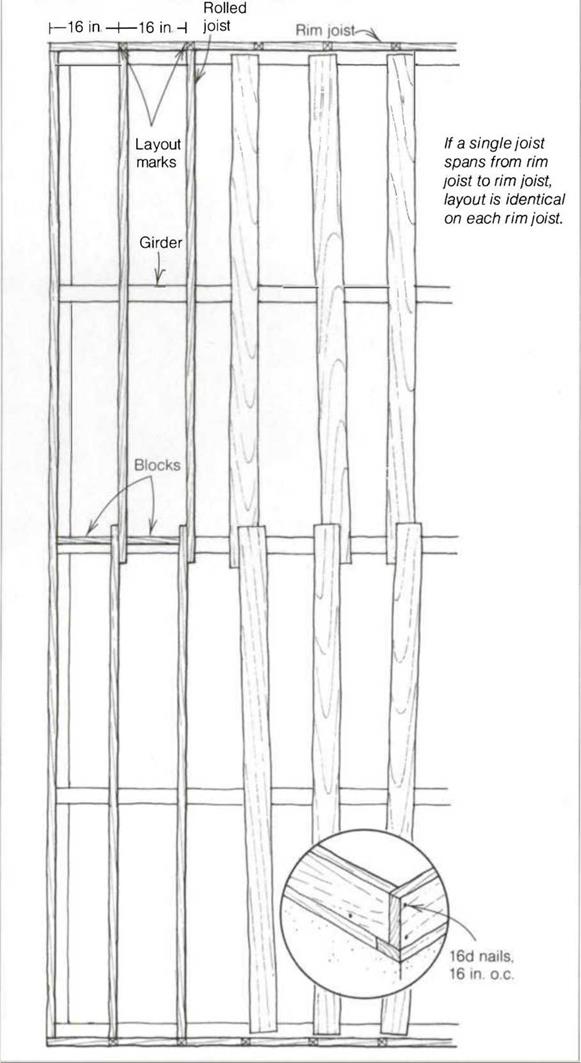

Once the joists are cut to length, it’s time to "roll" them. Rolling means to set floor joists on edge and nail them in place with their crown (the slight bow along the bearing edge) up. Line up each joist with the layout marks on the

Once the joists are cut to length, it’s time to "roll" them. Rolling means to set floor joists on edge and nail them in place with their crown (the slight bow along the bearing edge) up. Line up each joist with the layout marks on the