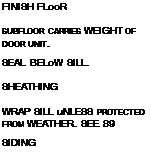

Principles of Data Collection and Storage

It is a general rule that data must always be collected with a specific purpose in mind. This rule is as much true concerning contaminant levels in soils and groundwaters as it is in any other field. Therefore, before any sampling regime is contemplated and before any specimens are analysed, it is essential to decide the purpose for which samples and analyses might be required. Then a systematic sampling programme and network needs to be designed and planned with the purpose and constraints clearly in view. It is usually a non-routine task to identify the questions that need answering by the sampling and analysis programme. Perhaps these will be suggested because of standards set by an environmental regulator...

read more