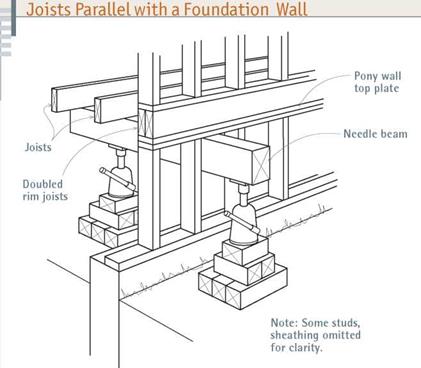

Needle Beams

When replacing a mudsill or sections of a foundation whose joists run perpendicular to that foundation wall (see p. 210), place a 4×8 or 4×10 carrying beam on edge under the house, within 2 ft. of the foundation. A jack every 6 ft. under the beam should suffice.

When joists run parallel to the foundation wall being replaced, you’ll need to run needle beams through exterior walls, and support each beam with one post underneath the house and a second post outside, roughly 2 ft. beyond the foundation wall. For this, you’ll need to remove sections of siding so you can insert a beam every 6 ft. to 8 ft. If the siding is stucco, you’ll need to punch large holes through it. To keep the rim (outer) joist from deflecting under the load, nail a second rim joist to it, doubling it before jacking...

read more

At Woodpointe, the Knoxville/ Knox County Planning Commission approved modifications in right-of-way, road width, and road construction requirements, as follows:

At Woodpointe, the Knoxville/ Knox County Planning Commission approved modifications in right-of-way, road width, and road construction requirements, as follows: