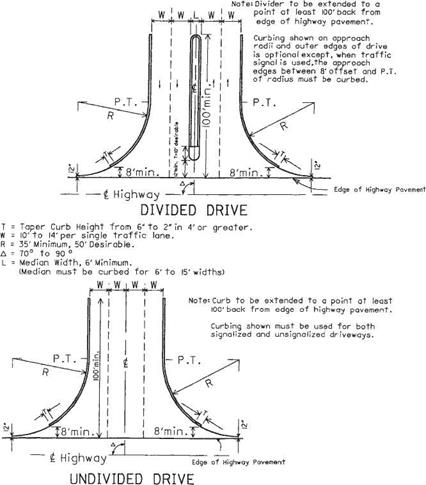

Drive Profile Design

Drive profiles on uncurbed roadways should slope down and away from the pavement

edge at the same slope as the graded shoulder. Any vertical curve should be developed

|

FIGURE 2.57 Designs for shopping center and industrial drives. Conversions: 1 ft = 0.305 m, 1 in = 25.4 mm. (From Location and Design Manual, Vol. 1, Roadway Design, Ohio Department of Transportation, with permission) |

outside the normal graded shoulder width. Vertical curve lengths should be 10 to 20 ft (3.0 to 6.1 m), depending on the grade differential. Under normal circumstances, rural drive grades should not exceed 10 percent, with 8 percent the preferred maximum.

The drive profiles for curbed roadways were developed using the design vehicle described in Fig. 2.50...

read more