SKYLIGHT AND RIDGE FLASHING

Skylight flashing is discussed in Chapter 6, where you’ll see an installation from framing to flashing. As a general rule, follow the instructions in the flashing kit provided by the skylight manufacturer.

Traditionally, ridges were flashed with a continuous strip of 12-in.-wide, 30-lb. building paper folded lengthwise, which straddled the ridge and overlapped the top courses of shingles. The build-

|

CHIMNEY FLASHING

|

1. As you roof along a chimney, alternate shingles and L-shaped pieces of step-flashing. Counterflashing will cover the tops of the step-flashing. For extra protection, run a bead of urethane between the stepflashing and the chimney. Press the flashing into the urethane to achieve a positive seal. |

|

3. Counterflashing is held in place by a folded – back lip jammed into the mortar joint. For good measure, the mason hammered masonry nails into the mortar, and then used a cold chisel to set them deeper. |

![]()

ing paper was then covered with a shingle saddle or overlapped ridgeboards. Metal flashing was sometimes used instead of building paper.

ing paper was then covered with a shingle saddle or overlapped ridgeboards. Metal flashing was sometimes used instead of building paper.

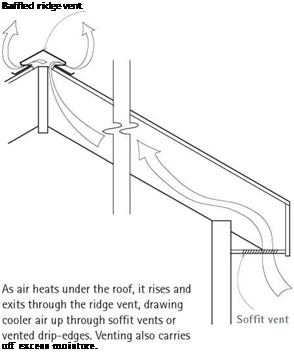

These days, ridges aren’t sealed by flashing. Instead they are often covered with ridge vents that allow hot air to escape, as shown on p.82.

Leave a reply