Mixing SMA with a Granulated Stabilizer

There is a widespread opinion among a large body of practitioners in the field of SMA production that, after all, the sequence of mixing should vary, depending on the kind of stabilizer. In the case of a granulated stabilizer, this is typically batched with the filler and then mixed with the aggregate without any special extra time for dry mixing (Figure 9.3). The extension of mixing time comes after the binder injection into the pugmill, where an additional 10 seconds of wet mixing time is provided (Graf, 2006). In Figure 9.4, another approach to the mixing sequences of granulated stabilizer is shown.

Although some claim that the use of granulated stabilizers does not involve the extension of the dry mixing time, we might—depending on job site results (i. e., fat spots)—be faced with the necessity of such an action to ensure that the granulate has been fully disintegrated.

FIGURE 9.3 The batching sequence of SMA mixture constituents into a pugmill with the use of a granulated cellulose fiber stabilizer. Notice that time depends on the type of pugmill. (From Graf, K., Splittmastixasphalt – Anwendung und Bewahrung. Rettenmaier Seminar eSeMA’06. Zakopane [Poland], 2006. With permission.)

|

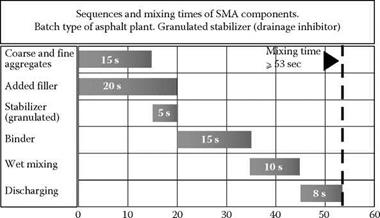

Seconds FIGURE 9.4 Batching sequence of SMA mixture constituents into a pugmill with the use of a granulated cellulose fiber stabilizer. Notice that time depends on the type of pugmill. (From Schunemann, M., Faserqualitat. Eine wesentliche Voraussetzung zum Herstellen von qualitatsgerechten Asphaltbefestigungen. Rettenmaier Seminar eSeMA’07, Zakopane [Poland], 2007.) |

Leave a reply