Pipe Deflection by the Iowa Formula

Deflection of flexible pipes is not a design criterion in most specifications, because if pipes are properly installed with approved soil and compaction level, deflections will be within normal limits. However, the deflection for given loading and backfill conditions

|

can be approximated for a round pipe. The traditional method of predicting deflection is the Iowa formula introduced by M. G. Spangler and modified by R. K. Watkins:

![]() DTKWr

DTKWr

AX = ______ _ c______________

|

|

EI + 0.061Er*

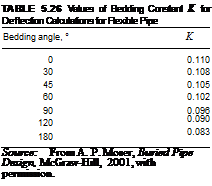

Values for the bedding constant may be found in Table 5.26. Because the bedding constant does not vary greatly and the bedding angle is generally not well known, it is often taken as 0.10. Values of the modulus of soil reaction are given in Table 5.27...

read more

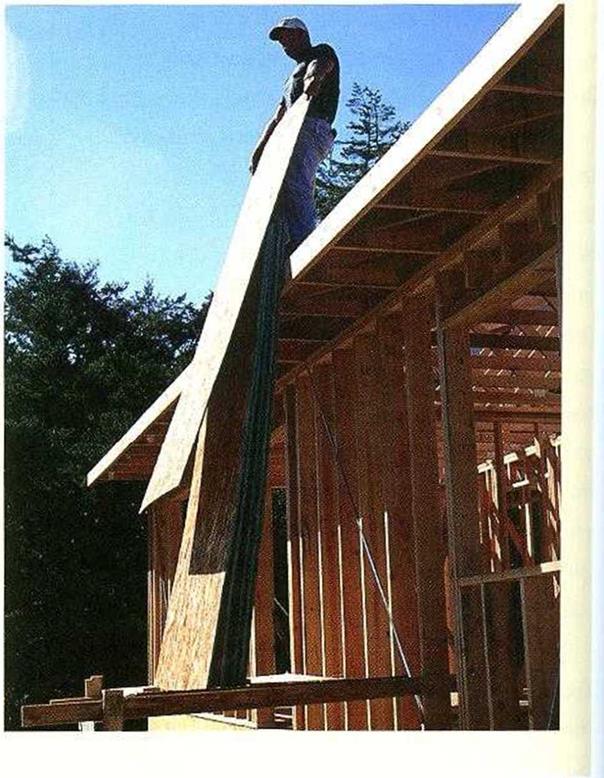

A SAFE STRATEGY for hoisting sheathing onto a roof is to build a simple staging platform, as shown in the photo at right. Nail the platform’s two horizontal supports (a pair of 2x4s works fine) to the wall framing or, if the wall has been sheathed already, to a 2x cleat nailed through the sheathing and into the studs. The supports must be a couple of feet above the bottom plate of the wall. Space them about 32 in. apart, and make them roughly level. Support the outboard end of the platform with 2x legs firmly attached to the horizontal supports. Nail a 2x on top of the platform near the outer end to provide additional stability. If necessary, install diagonal braces between the supports and the legs or the wall framing for added strength...

A SAFE STRATEGY for hoisting sheathing onto a roof is to build a simple staging platform, as shown in the photo at right. Nail the platform’s two horizontal supports (a pair of 2x4s works fine) to the wall framing or, if the wall has been sheathed already, to a 2x cleat nailed through the sheathing and into the studs. The supports must be a couple of feet above the bottom plate of the wall. Space them about 32 in. apart, and make them roughly level. Support the outboard end of the platform with 2x legs firmly attached to the horizontal supports. Nail a 2x on top of the platform near the outer end to provide additional stability. If necessary, install diagonal braces between the supports and the legs or the wall framing for added strength...