Techniques MAKING A PLATFORM FOR ROOF SHEATHING

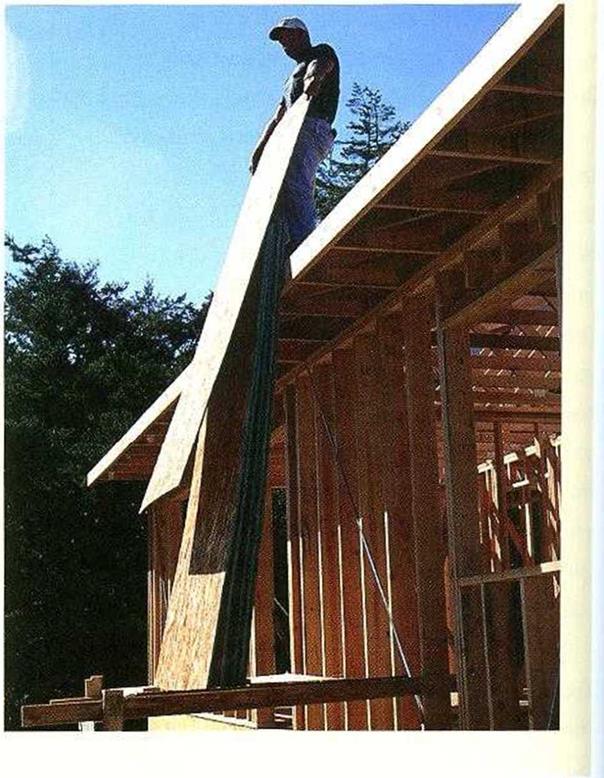

A SAFE STRATEGY for hoisting sheathing onto a roof is to build a simple staging platform, as shown in the photo at right. Nail the platform’s two horizontal supports (a pair of 2x4s works fine) to the wall framing or, if the wall has been sheathed already, to a 2x cleat nailed through the sheathing and into the studs. The supports must be a couple of feet above the bottom plate of the wall. Space them about 32 in. apart, and make them roughly level. Support the outboard end of the platform with 2x legs firmly attached to the horizontal supports. Nail a 2x on top of the platform near the outer end to provide additional stability. If necessary, install diagonal braces between the supports and the legs or the wall framing for added strength. Then set 4×8 sheets of plywood or OSB on edge on the platform; workers on the roof can grab the sheets as needed.

A SAFE STRATEGY for hoisting sheathing onto a roof is to build a simple staging platform, as shown in the photo at right. Nail the platform’s two horizontal supports (a pair of 2x4s works fine) to the wall framing or, if the wall has been sheathed already, to a 2x cleat nailed through the sheathing and into the studs. The supports must be a couple of feet above the bottom plate of the wall. Space them about 32 in. apart, and make them roughly level. Support the outboard end of the platform with 2x legs firmly attached to the horizontal supports. Nail a 2x on top of the platform near the outer end to provide additional stability. If necessary, install diagonal braces between the supports and the legs or the wall framing for added strength. Then set 4×8 sheets of plywood or OSB on edge on the platform; workers on the roof can grab the sheets as needed.

drive up my heart rate at the beginning of the day but not an experience I’d care to repeat, lake care, and stay aware.

Measure 4814 in. from the edge of the gutter or fascia board at each end of the roof and snap a chalkline. Lay the first row of plywood or OSB so that the top edge is right on this line (see the photo at left). Make sure the sheathing extends past the gable-end truss all the way to the barge rafter, which the sheathing helps support. Lay the slick side of the OSB down. Kail the sheets with 8d nails at 6 in. o. c. at the edges and 12 in. o. c. in the field. Be sure to nail all the boards.

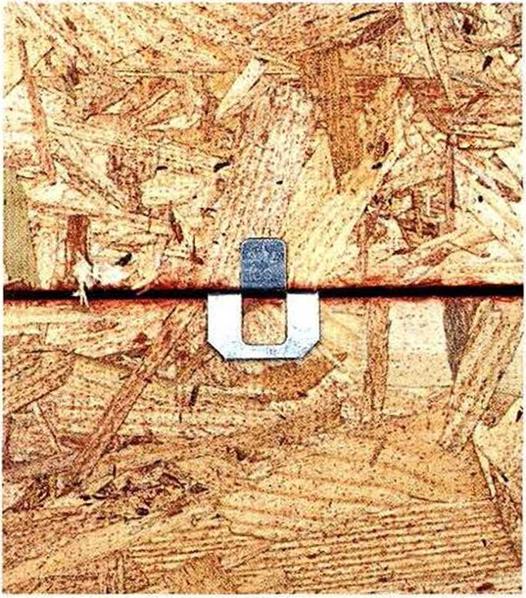

Before vou start the second row of sheath-

/

і tig, put plywood 11-dips, centered between the rafter chords, on the first row (see the photo on the lacing page). Required on ‘/An.

sheathing (but not on %-in. sheathing), these clips hold each row together and make the roof’s surface stronger. Start the second row at one end with a 4-ft.-scj. sheet so that the courses will he staggered, just as they are with floor sheathing. Continue sheatiing until von reach the top. If a ridge vent will be installed, leave a gap at the ridge so that air inside the attic can move up into the vent. If the vent is available, read the manufacturers instructions regarding the size of the gap and check with your building inspector regarding these construction details. The gap need not run all the way to the barge rafter. Start it about 1 ft. in on the main rook

sheathing (but not on %-in. sheathing), these clips hold each row together and make the roof’s surface stronger. Start the second row at one end with a 4-ft.-scj. sheet so that the courses will he staggered, just as they are with floor sheathing. Continue sheatiing until von reach the top. If a ridge vent will be installed, leave a gap at the ridge so that air inside the attic can move up into the vent. If the vent is available, read the manufacturers instructions regarding the size of the gap and check with your building inspector regarding these construction details. The gap need not run all the way to the barge rafter. Start it about 1 ft. in on the main rook

Leave a reply