FRAMING

Framing a roof is the most difficult aspect of framing, and the ability to construct a roof is a real test of your framing skills. This chapter has three separate sections. The first addresses basic rafter framing, including roof framing terms, roof styles, five methods of finding rafter lengths, the eleven steps for framing a roof with rafters, and ceiling joist information.

The second section of the chapter covers finding rafter lengths using the “Diagonal Percent" method. You can follow an example to learn how to cut difficult rafters. If you master this system, you will be able to “cut and stack" a roof, which means you can cut all the rafters and stack them ready for installation before the first one is installed. If you are familiar with the basics of rafter cutting, you might want to skip to this section. Some of the basic steps are duplicated for the example. The final section of the chapter discusses the eight steps of roof truss framing.

Roof trusses are typically pre-manufactured off site and delivered to the job site. They are engineered for strength and use standard dimension lumber. Gang nail plates are used to connect the cords and struts that make up the trusses.

The angles and pitches of a roof are as varied as the colors in a child’s crayon box. Just as some colors

have certain characteristics in common, so do rafters and trusses. This chapter is organized around these common characteristics. Key steps for framing a roof with rafters and trusses are provided.

The most difficult part of framing a roof is finding the rafter length. It is based on the relationship between the rise (vertical) distance and the run (horizontal) distance. In this chapter, you’ll find methods for finding the rafter length, though you ultimately will only need to memorize the approach you’re most comfortable with. You will also find that at different times you might want to use different methods.

Prefabricated trusses, factory-made from the architect’s specifications, require, of course, no calculations on your part. Uniform in size, they are somewhat easier to work with than ridgeboards and rafters. Still, they are heavy to work with, especially working at heights.

This chapter starts with important rafter terms, followed by steps for calculating and cutting rafters and installing sheathing. The second half of the chapter provides more detailed information and examples on finding rafter length. The chapter ends with a discussion of joists and trusses.

Hip rafter

Span—the distance between two supporting members, typically measured from the outside of two bearing walls.

Run—horizontal distance.

Rise—vertical distance.

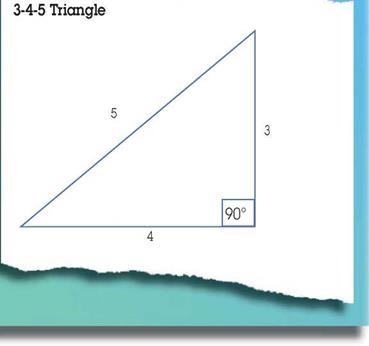

Diagonal—the distance between the far point on the run and the high point on the rise. (Similar to hypotenuse in mathematical terms.)

Hip or valley run—the horizontal distance below the hip or valley of a roof, from the outside corner of the wall to the center framing point.

Overhang hip run—the horizontal distance below the overhang hip of the roof, from the outside corner of the wall to the outside corner of the fascia.

Hip or valley diagonal—the distance between the far point on the hip or valley run and the high point on the hip or valley rise.

Overhang diagonal—the distance between the far point on the overhang run and the high point on the overhang rise.

Diagonal percent—the diagonal divided by the run.

Hip-val diagonal percent—the hip or valley diagonal divided by the hip or valley run.

Rise percent—the rise divided by the run.

Pitch—the slope of the roof, or the relationship of the run to the rise. Typically defined as a certain height of rise for 12 units of run for a common rafter, and 17 (16.97) units of run on a 90° hip or valley rafter.

Framing point—the point where the center lines of connecting rafters, ridges, hips, or valleys would meet.

Cheek cut—an angle cut that is made to bear against another rafter, hip, or valley.

Common rafter—a rafter running from a wall straight to a ridge board.

Jack rafter—a rafter running to a hip rafter or a valley rafter.

Hip rafter—a rafter at an outside corner of a roof that runs in between and joins jack rafters that bear on corner walls.

Valley rafter—a rafter at an inside corner of a roof that runs between and joins with jack rafters from each side.

Ridge end rafter—a rafter that runs from the end of a ridge.

Pitch angle—the vertical angle on the end of a rafter that represents the pitch of the roof.

Connection angle—the horizontal angle at the end of a rafter needed to connect to other rafters, hips, valleys, or ridge boards.

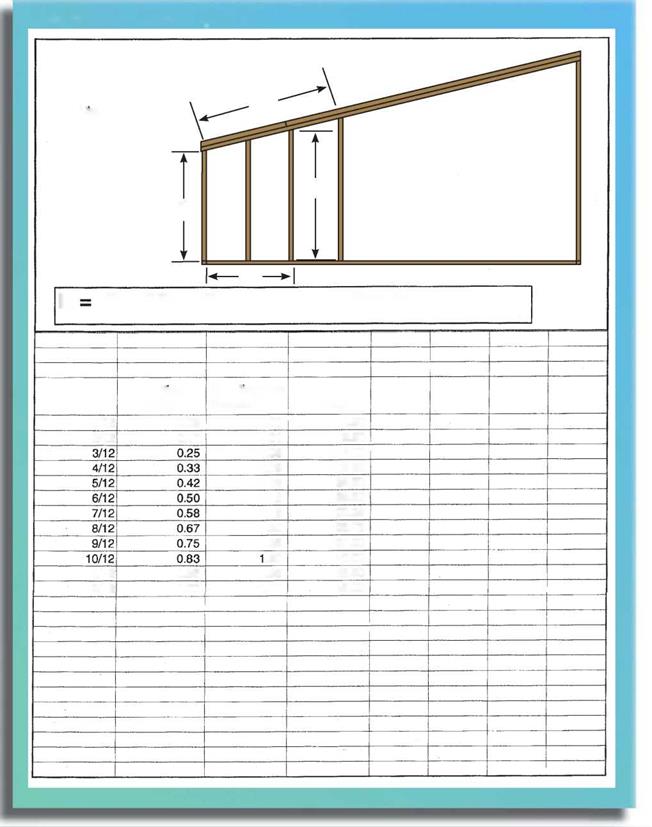

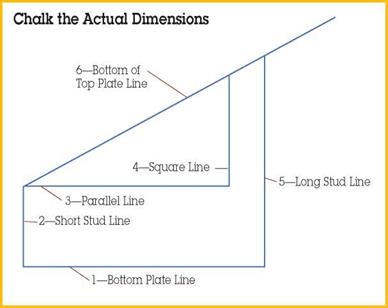

Chalk a square line (4) to the parallel line that is close to the long stud line (5), but convenient for figuring its length. The length of the square line (4) will be in a relationship to the parallel line (3), depending on the pitch of the rake wall. If, for example, the pitch is 6/12 and the parallel line is 12, the square line will be 6.

Chalk a square line (4) to the parallel line that is close to the long stud line (5), but convenient for figuring its length. The length of the square line (4) will be in a relationship to the parallel line (3), depending on the pitch of the rake wall. If, for example, the pitch is 6/12 and the parallel line is 12, the square line will be 6.

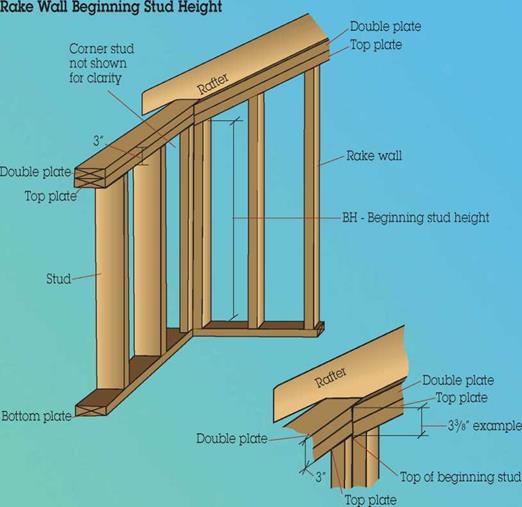

A typical beginning height would be slightly lower than the adjoining wall, as shown in the "Rake Wall Beginning Stud Height" drawing.

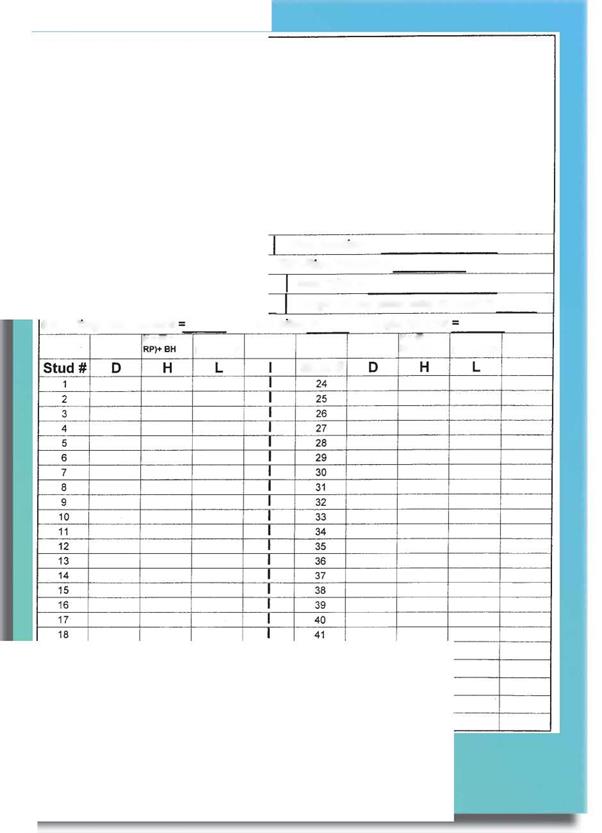

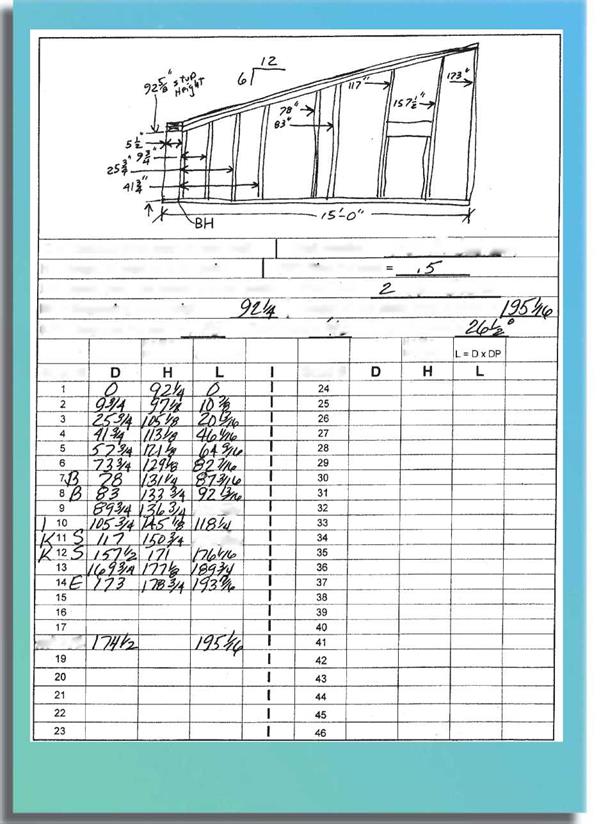

A typical beginning height would be slightly lower than the adjoining wall, as shown in the "Rake Wall Beginning Stud Height" drawing. The stud height to the short point is found by using the formula (D x RP) + BH. RP is the rise percent, or the relationship between the rise and the run. The relationship gives you the height increase of the studs per increase in the distance of the plate. This relationship is illustrated in the filled-in version of the Rake Wall Stud Heights Worksheet. The formula for finding RP is also shown, in the "Rise & Diagonal Percent" illustration later in this chapter.

The stud height to the short point is found by using the formula (D x RP) + BH. RP is the rise percent, or the relationship between the rise and the run. The relationship gives you the height increase of the studs per increase in the distance of the plate. This relationship is illustrated in the filled-in version of the Rake Wall Stud Heights Worksheet. The formula for finding RP is also shown, in the "Rise & Diagonal Percent" illustration later in this chapter.

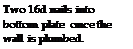

Lasers are good for taller walls. Lasers are not dependent on perfect wood for determining plumb. Set the laser at the bottom, and read the distance you set at the bottom on your tap at the top of the wall. If you need to check plumb on a regular basis, the laser has the advantage of fitting in your pouch.

Lasers are good for taller walls. Lasers are not dependent on perfect wood for determining plumb. Set the laser at the bottom, and read the distance you set at the bottom on your tap at the top of the wall. If you need to check plumb on a regular basis, the laser has the advantage of fitting in your pouch.

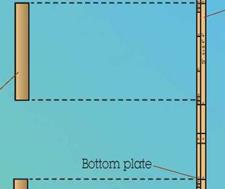

Nail on the inside of the bottom plate so the nails will hold the wall in position while it is being stood. The bottom plate should be nailed so that it’s in line with the wall chalk line. Then, when the wall is raised, it will be in the right position.

Nail on the inside of the bottom plate so the nails will hold the wall in position while it is being stood. The bottom plate should be nailed so that it’s in line with the wall chalk line. Then, when the wall is raised, it will be in the right position.

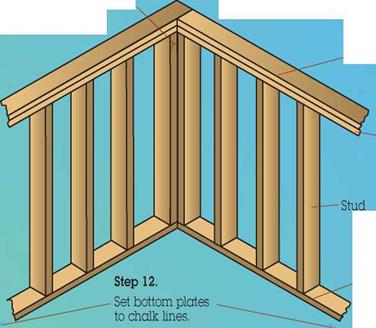

Cover the entire wall with sheathing, then rout window and door openings with a panel pilot router bit (see illustration). Save the leftover pieces of sheathing for small areas and filling in between floors.

Cover the entire wall with sheathing, then rout window and door openings with a panel pilot router bit (see illustration). Save the leftover pieces of sheathing for small areas and filling in between floors.

ачіш

ачіш

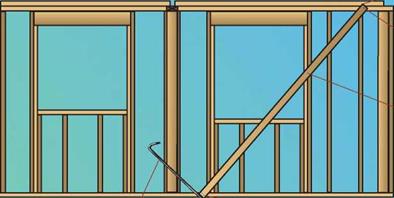

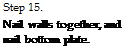

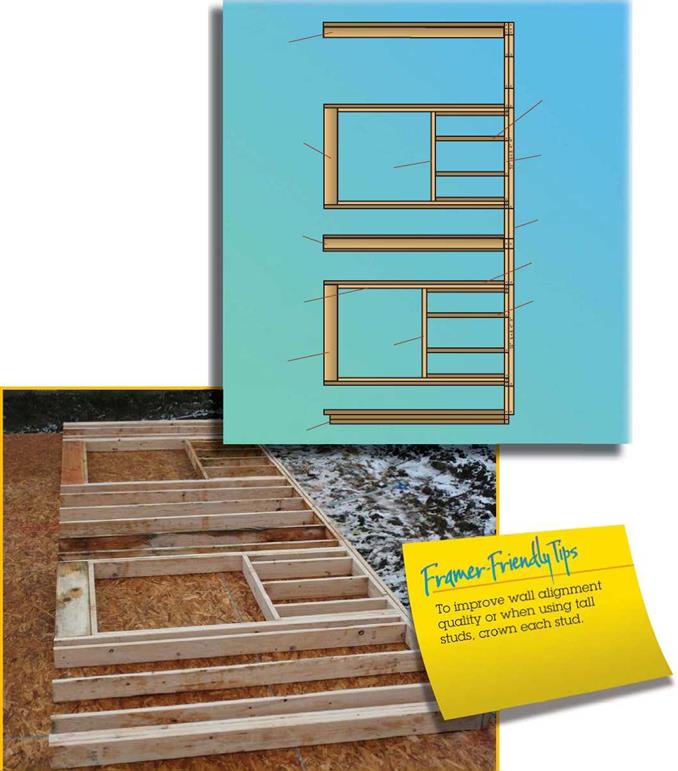

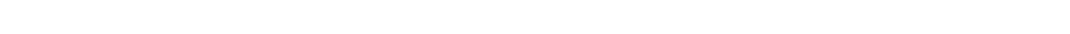

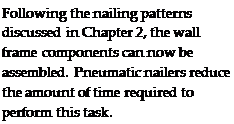

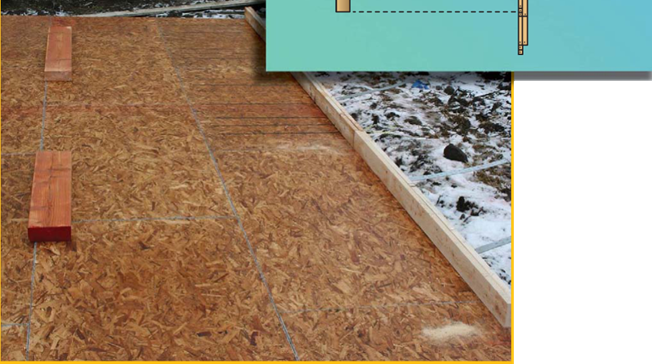

The steps outlined in the next pages follow the process of framing and sheathing the exterior walls in a horizontal position. The fully framed and sheathed wall is then lifted into position by using special lifting jacks or muscle power.

The steps outlined in the next pages follow the process of framing and sheathing the exterior walls in a horizontal position. The fully framed and sheathed wall is then lifted into position by using special lifting jacks or muscle power.