I-JOIST CUTTING GUIDE

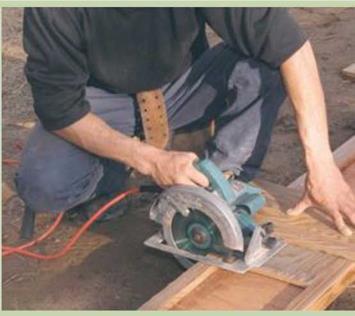

I-joists are awkward to cut because the top and bottom chords are wider than the web. To overcome this difficulty, make a simple jig with 3/4-in.-thick plywood. Cut a rectangular piece of plywood to fit between the chords and serve as the base of the jig. Screw a longer piece to the first piece, positioning it to guide a 90-degree cut. The edge of the top piece guides the base of the circular saw, as shown in the photo at right. Lay the guide on the I-joist, set the saw on it, and make a square cut. It’s that simple.

I-joists are awkward to cut because the top and bottom chords are wider than the web. To overcome this difficulty, make a simple jig with 3/4-in.-thick plywood. Cut a rectangular piece of plywood to fit between the chords and serve as the base of the jig. Screw a longer piece to the first piece, positioning it to guide a 90-degree cut. The edge of the top piece guides the base of the circular saw, as shown in the photo at right. Lay the guide on the I-joist, set the saw on it, and make a square cut. It’s that simple.

Cut I-joists with a guide. Scrap sheathing that is nailed or screwed together creates an effective guide for cutting I-joists. [Photo by Roe A. Osborn, courtesy Fine Homebuilding magazine © The Taunton Press, Inc.]

swell, shrink, crack, or warp the way solid lumber does...

read more

![TOENAILING BASICS Подпись: The girders that support the joists need to break over a post. [Photo by Don Charles Blom]](/img/1312/image219_1.gif)

A majority of the projects in the Joint Venture for Affordable Housing (JVAH) were developed under some version of Planned Unit Development zoning or subdivision regulations.

A majority of the projects in the Joint Venture for Affordable Housing (JVAH) were developed under some version of Planned Unit Development zoning or subdivision regulations.

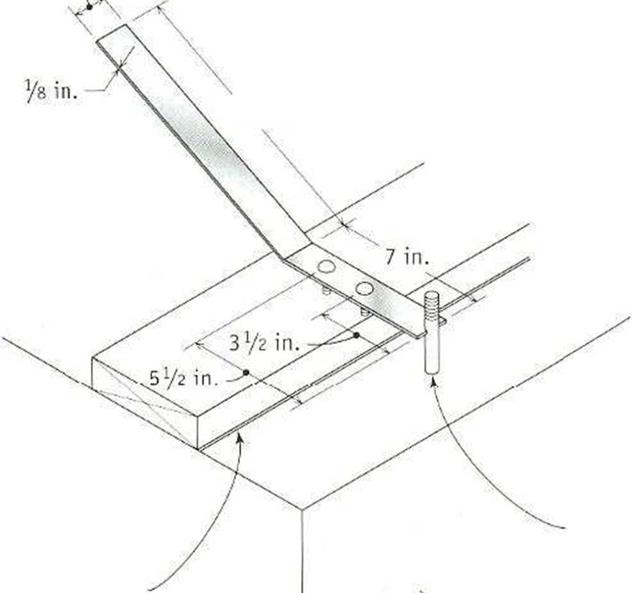

Select an 18-in. by іУг-іп. by Vs-in. metal plate strap.

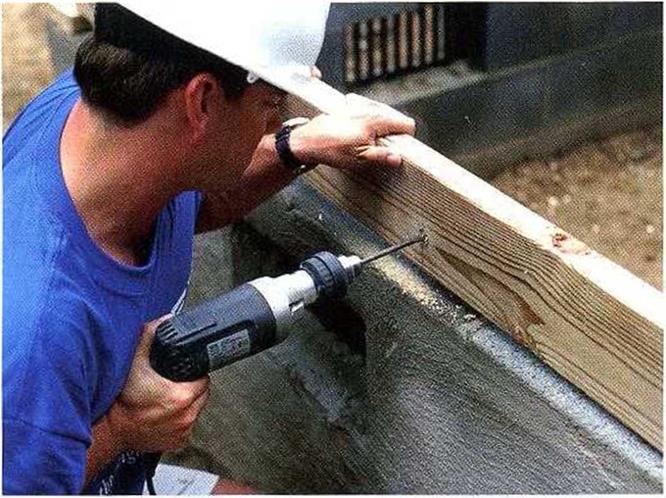

Select an 18-in. by іУг-іп. by Vs-in. metal plate strap. A bolt-hole marker makes it easy to transfer the bolt location to the sill in preparation for drilling a hole.

A bolt-hole marker makes it easy to transfer the bolt location to the sill in preparation for drilling a hole.