Chemical Analysis

Chemical analysis allows determination of the chemical composition of collected samples and, therefore, to identify specific compounds in the chosen environment. Each chemical compound has one or more analytical methods, from the many different methods available, that are more suitable for obtaining an accurate determination of concentration. This section of this chapter presents a brief summary of the analytical methods most used at present for chemical composition identification. It includes coverage of toxicity tests that properly supplement chemical analyses when used to assess the possible impact on living organisms.

7.6.2.2 Selective Ion Measurement

Ion selective electrodes (ISE) are membrane electrodes that respond selectively to specified ions in the presen...

read more

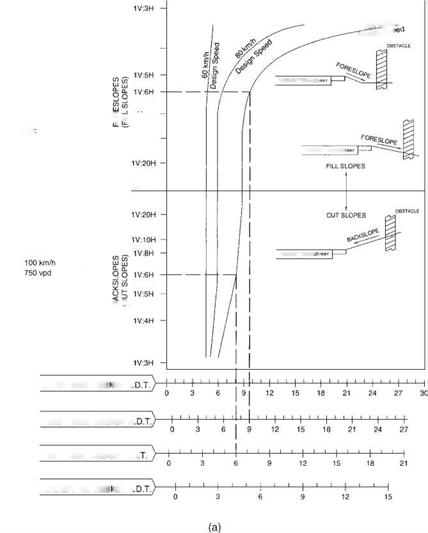

CLEAR-ZONE DISTANCE (m)

CLEAR-ZONE DISTANCE (m)