Posted by admin on 19/ 11/ 15

For those of you who say, "I don’t do windows," technology has finally caught up with your sentiment. Several big glass companies market coated glass that resists the buildup of dirt. Product names include Neat® Glass by Cardinal, Activ™ by Pilking – ton®, and PPG’s SunClean®.

By making the glass smoother and hydrophilic, rainwater collects in sheets on the surface and slides off the glass quickly, cleaning the window. Some windows include a titanium-dioxide layer that reacts with UV – light to help organic materials decompose, so dirt washes away more easily.

Window Styles

DOUBLE-HUNG

Traditional window composed of two sashes that slide vertically. A single-hung window looks identical, but the top sash is fixed.

Pros: Available with a wide variety of grille patterns to match different architectural styles.

Sashes usually tilt in for easy cleaning of the exterior.

Cons: Sashes rely on draftier sliding-style weatherstripping. The bottom edge of the upper sash is exposed to outdoor temperatures on two faces, increasing surface area for thermal bridging. Two sashes increase spacer area, increasing U-factor. Less than half the window area can be open for ventilation.

AWNiNG

Top-hinged window that usually opens outward with a crank.

Pros: Good-sealing compression-style weatherstripping. Single glass unit and recessed sash improve U-factor. Provides ventilation while it’s raining. Often used above and/or below large fixed windows for ventilation and additional daylight.

Cons: Screen on inside of window. Open window can present a hazard if installed along a walkway, deck, patio, or porch.

TiLT-AND-TURN

Dual-action window that can swing in like a door or tilt from the bottom like a hopper window for ventilation.

Pros: Ventilation options. Secure multipoint locking. Compression weatherstripping. Large egress area and easy cleaning.

Cons: Shades and drapes can interfere with operation.

CASEMENT

Side-hinged window that usually opens outward with a crank. In-swing versions are available.

Pros: Compression-style weatherstripping. Single large glass unit and recessed sash im

prove U-factor. Largest ventilation area of any window style. Opening can be oriented to "scoop" prevailing breeze.

Cons: Screen on inside of window. Hinge design might not allow outside of window to be cleaned from inside. Open window can present a hazard if installed along a walkway, deck, patio, or porch.

HORiZONTAL SLiDER

The two sashes slide past one another on tracks like a sliding patio door.

Pros: Can be easier to open than other sliding styles, especially when placed over a counter.

Cons: Sliding weatherstripping and greater sash area lower U-factor and airtightness ratings.

FiXED

An inoperative window available in shapes that match operable windows, or as accent windows such as half-rounds to create Pal- ladian windows and octagons.

Pros: Improved airtightness. Can be made in nonstandard, custom shapes.

Cons: Doesn’t satisfy egress requirements.

HOPPER HOPPER

Tilt-in bottom-hinged window.

Pros: Compression-style weatherstripping. Single glass unit and recessed sash improve U-factor.

Cons: Hazardous if installed at head height or lower.

Choosing

Replacement

Windows

You have three choices for replacing existing windows: a sash-only replacement; an insert-style frame and sash replacement window; or a new-construction window.

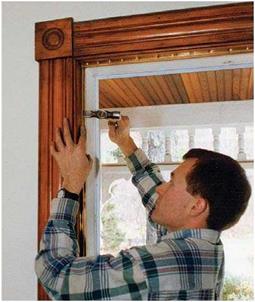

If the existing frames have water damage, the only choice is a new-construction window (see the photos on p. 92).

If you’re looking to improve comfort or energy performance, replacing the sashes or using a frame insert can help. They’re a good choice on older homes where you want to preserve period trim, but from an energy and comfort standpoint, they’re not the best option.

Replacement windows that leave the existing frame in place don’t stop air leakage. If you’ve ever pulled out an old window, then you’ve seen fiberglass insulation stuffed between the window and the rough opening. Typically, the insulation is dirty. It wasn’t dirty when it was put there; dirt was filtered out of the air moving through and around the window frame.

Another negative is that insert-style frame and sash replacement windows reduce the glass area because the unit fits inside the existing frame. You might be willing to live with diminished views, but are you willing to pay for that privilege every year? In a southern climate, the reduced glass area does not affect heating bills, but in northern heating climates, reducing the south-facing glass area gives away a lot of free heat.

An insert-style frame and sash replacement window is generally a bit pricier than a

new-construction window. Installation costs are lower, however, because it leaves the existing trim in place and doesn’t require any siding removal.

Regardless of the type you choose, replacement windows are expensive. If you’re trying to save on energy expenses, new windows shouldn’t be considered until you have improved the insulation and the air-tightness of the rest of the building envelope.

Former Fine Homebuilding editor Sean Groom is a

freelance writer in Bloomfield, Conn. freelance writer in Bloomfield, Conn.

|

replacement

|

Posted by admin on 19/ 11/ 15

Another way to control the flow of heat through a window is with suspended films. These films come in two varieties: high solar gain and low solar gain.

Because these films (similar to mylar) are so lightweight and thin, as many as three films can be suspended between two glass panes. The additional insulating spaces increase the insulating ability of the window, replicating the performance of three-, four-, or five-pane windows without the weight. Serious Windows® uses this approach to create high-performance windows with both high and low solar-gain properties. The company’s premium fixed window has an insulating value of R-11.1 (U-factor 0.09), nearly rivaling many wall insulations. The operable version of the window is R-7.1 (U-factor 0.14). Considering that the average insulating window is the equivalent of R-1 to R-3, Serious Windows live up to their name.

Let the Light Shine In

Solar gain and insulating values aren’t the only ways that windows save energy and keep you comfortable. Windows also control the view and the amount of natural light.

Daylighting, or window-placement strategies to maximize natural light, save money by reducing the need for electric lighting. Although placement is a design issue, window styles and glass properties affect the amount of light infiltration. The visible transmittance (VT) rating on the National Fenestration Rating Council’s label (p. 95) allows you to compare the amount of light that passes through windows, taking into account the light blocked by frames and grilles.

Impact-Resistant Glass Offers Protection Impact-Resistant Glass Offers Protection

Although they don’t affect a window’s energy performance, a few options can make you safer.

Tempered glass, for example, can be specified for windows located where someone could potentially fall into one. Many of these locations are covered by code and include windows within 18 in. of the floor, next to doors, in showers or bath areas, and along decks, patios, and walkways.

If you live in a coastal area—particularly along the Atlantic and Gulf coasts, where building codes demand protection during hurricanes—or in a tornado-prone area, you can specify impact-resistant glass. Using the same technology as car windshields, a plastic sheet is laminated between two pieces of glass so that the window maintains its integrity after the glass is broken.

Window frames can also be reinforced to withstand impact. Available in three different strengths (impact zones 2, 3, and 4), the toughest windows in impact zone 4 must withstand strikes from at least two 8-ft.-long 2x4s traveling at 50 ft. per second, followed by 9,000 cycles of negative and positive pressure simulating hurricane-force winds.

Windows That Keep the World at Bay

Manufacturers also offer variations of pebbled, frosted, and wavy glass that add privacy to bathrooms, bedrooms, and other sensitive spaces.

If you live near a busy road, near train tracks, or under a flight path, acoustic windows can take the edge off loud or constant noise. Even if they don’t readily advertise the fact, many window companies sell sound-attenuating windows. Residential "quiet" windows are likely to be rated with a sound transmission coefficient (STC). A typical double-pane window has an STC of 25 to

27. Every increase of 10 in the STC cuts the amount of sound transmitted by half. Companies such as Milgard®, Atrium®, Marvin, and Serious Windows have windows in the 40 to 47 STC range.

Posted by admin on 18/ 11/ 15

Energy-efficient windows were developed during the previous energy crisis. When Jimmy Carter was installing solar panels on the White House and making conservation a priority, the Department of Energy’s Lawrence Berkeley National Laboratory was charged with finding ways to conserve energy. Windows were among their targets. The insulating windows of that era allowed an inordinate amount of heat to escape. The lab’s scientists concluded that by using existing technologies to deposit a virtually invisible metal or metal-oxide coating on the glass, insulating windows could be dramatically more efficient. This coating is transparent to visible light, but blocks long – and short-wave radiation by reflecting it. Known as a low-e (for low-emissivity) coating, it’s common today even on low-cost windows.

Depending on the nature of this thin coating and which window surface it is applied to, the coating can reflect heat back into the room to conserve it or filter sunlight to keep heat out. Using a coating on two different glass panes can fine-tune the amount of heat that’s retained in each direction.

The measure of the amount of the sun’s heat a window lets through is the solar heat gain coefficient. SHGC in shorthand, it ranges from 0 to 1, where 1 is uninterrupted heat gain. A clear-glass, two-pane insulated window has an SHGC between 0.56 and 0.68, depending on the frame material and construction. The size of the air gap, which is influenced by frame design, and the amount of light blocked by the frame and grille affect the SHGC.

A double-pane IG with two low-e coatings can achieve an SHGC of 0.33 (glass-only value). As the SHGC is minimized, the U – factor declines, which has implications for selecting windows in climates with heating and cooling seasons.

Choosing

Energy-Saving

Windows

REGiONAL: A GOOD APPROACH

If you’re interested in efficient windows, the starting point is an Energy Star rating. The greatest chunk of energy savings comes from good insulating properties. Energy Star performance prescriptions dictate that the colder the climate, the lower the U-factor you’ll want. In southern climates, where airconditioning dominates energy consumption, Energy Star ratings shift focus to a lower SHGC to reduce the impact of the sun.

The Department of Energy divides the United States into four climate regions (see the map on p. 98). Under the Energy Star program, each region is assigned threshold U-factor and SHGC ratings for a qualifying window (see the chart on p. 98). A double – hung vinyl window that’s Energy Star qualified in all four zones might start at around $14 per sq. ft., with a clad frame starting at around $28 per sq. ft.

< less than or equal to

DULUTH, MINN.

Insulated fiberglass frame, double pane with three films

U-factor = 0.09 (R-11)

SHGC = 0.26 Price = $280/sq. ft.

LoCAL: a Better APPRoACH

In the United States, the performance characteristics on an NFRC label (see the sidebar on p. 95) provide a moment-in-time snapshot of performance, but don’t relate anything about the long-term energy consequences and peak load demands of window choices.

To get a better-performing window than the Energy Star minimum, you need to take energy costs into account. A quick-and-dirty tool from the Efficient Windows Collaborative (www. efficientwindows. org/selection .cfm) compares the energy costs for a range of windows with different performance characteristics. The cost figures are generated using RESFEN software (see "Site Specific: The

san francisco, calif.

insulated vinyl frame, double pane with one film

U-factor = 0.27 (R-3.8)

SHGC = 0.47 Price = $50/sq. ft.

Best Approach" on p. 100) and are based on a benchmark house.

Their modeling recommends low U-factor, high-SHGC windows in the north region, the north/central zone, and the upper half of the south/central area; and low U-factor, low-SHGC windows in the southern reaches of the south/central area and in the south region.

The most energy-efficient windows in all locations, except San Francisco and Flagstaff, Ariz., are at least triple-glazed with insulated vinyl or fiberglass frames. These windows are hard to find and expensive. The nice thing about the collaborative’s website is that it shows how much annual energy expenditures rise if you opt for a readily

LOUiSViLLE, KY. insulated fiberglass frame, triple pane

U-factor = 0.23 (R-4.3)

SHGC = 0.39 Price = $80/sq. ft.

available double-glazed window with two low-e coatings and an uninsulated vinyl or clad-wood frame. Exceeding Energy Star minimums saves money over the life of the window. (Examples shown are options exceeding Energy Star thresholds. Consult the collaborative’s website or RESFEN for energy performance for your location. Prices are approximate window cost.)

Critics of Energy Star argue that in heating climates, the emphasis on insulating- value performance to the exclusion of solar heat gain misses an opportunity. By omitting an SHGC requirement in the north region, window companies can market a single low U-factor, low-SHGC glass package that meets Energy Star requirements in all regions. An Energy Star label on low U-factor, low-SHGC windows in cold northern regions of the United States means homeowners who think they are buying energy-efficient windows are actually paying more in heating costs and adding more carbon emissions to the atmosphere than if they had purchased windows that accounted for passive solar-heating opportunities. (For some sites, a very low U-factor, such as the Duluth, Minn., example, is the best option.) The Department of Energy is reportedly reevaluating the standard.

While insulating properties may not seem as important in the South, where Energy Star thresholds are fairly high, a low U-factor helps to keep indoor temperatures cool. This reduces peak cooling loads and saves money in two ways: It reduces energy consumption

new orleans, la.

Clad-wood frame, double pane

U-factor = 0.3 (R-3.3)

SHGC = 0.21 Price = $52/sq. ft.

in peak demand periods with higher rates, and by reducing peak loads saves on mechanical costs with a smaller airconditioning system.

Window glass isn’t the only or even the best way to block summer sun. Deciduous trees on the south, east, and west sides of a house work very well. Another strategy is the use of overhangs and shading devices.

If you need to rely on window glass to control solar gain in the South, you’ll need low-SHGC, or spectrally selective, windows. They reflect short – and long-wave infrared radiation to filter out 40% to 70% of incoming heat. Sometimes known as low-e2 or low-e3, the second – and third-generation low-emissivity coatings on these windows not only reduce solar gain, but also filter more than 99% of the UV-light that causes color fading.

Generally, you want a window to block solar gain but let in visible light. The window’s light-to-solar-gain ratio (VT/SHGC) provides a gauge of its relative efficiency in transmitting light while blocking heat gain. The higher the number, the more light transmitted without adding excessive amounts of heat. In a cooling-dominated climate, a ratio above 1.0 is better because light transmittance is higher than heat gain.

If glare is a problem, windows tinted bronze, green, or blue limit visible light and are spectrally selective with a low SHGC. However, because they absorb infrared radiation rather than reflect it, tinted windows radiate heat.

CANADIANS HAVE iT EASY

Windows sold in Canada have an energy rating (E. R.) that makes it easy to evaluate the trade-offs in heating-dominated climates.

By weighing the amount of solar-heat gain against interior-heat loss through the window and heat loss through air leakage, the E. R. indicates whether a window is a net source of energy (positive E. R. value), energy neutral (E. R. equals 0), or a net loss of energy (negative E. R. value). If you live in a north or north/central zone in the United States or Canada and you’re buying a window from a Canadian manufacturer, simply choose the highest E. R. possible.

SITE SPECIFIC: THE BEST APPROACH

Engineers and efficient-house designers use complex modeling software to evaluate the effect of window options on energy consumption. Rather than buying the same window for an entire house (as you would using Energy Star guidelines or the Efficient Windows Cooperative website), they tune the windows to optimize glass performance for each orientation.

The average homeowner or contractor can model the energy performance of a house and compare the effects of different windows with RESFEN, a free software package from the Department of Energy’s Lawrence Berkeley National Laboratory (http:// windows. lbl. gov/software/resfen/resfen .html). Unfortunately, to get the most out of the program, you’ll have to slog through the manual.

Generally, in heating climates, southfacing windows have a high SHGC (greater than 0.5), and east – and west-facing windows have a low SHGC (less than 0.3) to prevent solar gain in the summer.

Until recently, common wisdom was that the SHGC on north-facing windows should match east – and west-facing windows, but software modeling has shown that high – SHGC north-facing windows don’t lose any energy.

Posted by admin on 18/ 11/ 15

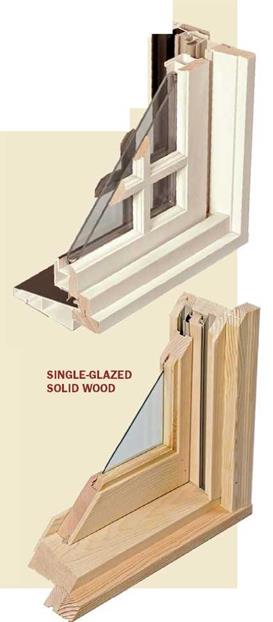

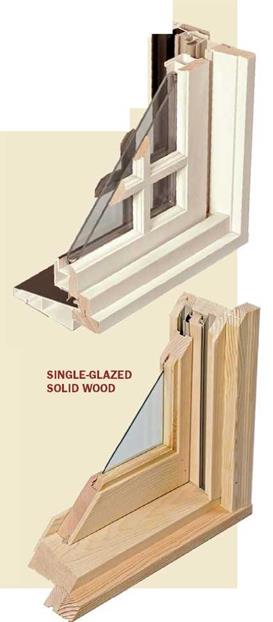

Manufacturers typically refer to glass as glazing. Using glazing as a noun is a bit pretentious, like referring to a window as a fenestration, but it does give the sense that glass assemblies in today’s windows are a far cry from the single-pane windows installed in the 1970s.

Those single-pane windows have been abandoned in most heating climates because glass is a horrible insulator. A standard window today relies on an insulated glass unit (sometimes called an IG). This unit is a sealed sandwich of two or three pieces of glass with an airspace between the panes. IG units are manufactured by a few glass companies that supply the hundreds of window manufacturers in North America.

ing decisions should be based on this number, which appears on the NFRC label (above). ing decisions should be based on this number, which appears on the NFRC label (above).

U-factors for operable windows range from 0.14 for a superinsulating suspended-film unit to 0.5 or so for a basic double-pane window from a big-box store. Lower U-factors correlate with higher prices.

The airspace between glass panes, usually V2 in. to 2/з in. thick, serves as insulation by reducing the transfer of heat through conduction. A single clear pane has a U-factor of 1.04, but a sealed double-pane unit has a U-factor of 0.5 (see "What’s a U-Factor?" above). Adding a third pane improves the U-factor to 0.3.

Replacing the air with gas improves the insulating value of the window. Manufacturers use argon or krypton gases because they’re inert—chemically stable and nonreactive— and because they reduce heat loss, as they are less conductive than air. Argon and krypton also reduce convective losses because the gases are heavier than air, reducing gas movement within the insulating space.

Krypton performs slightly better than argon, but its bigger advantage is that the optimal spacing between krypton-filled panes is narrower than what’s required for argon. That means less stress on the sashes, particularly in triple-pane windows.

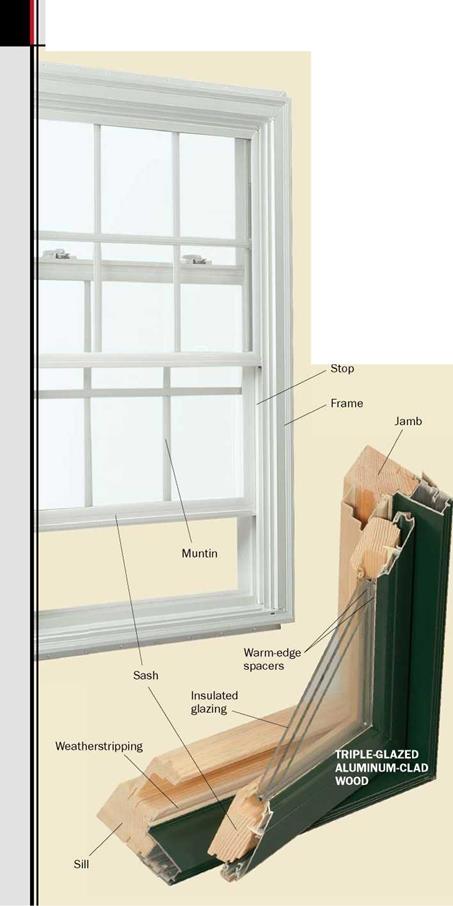

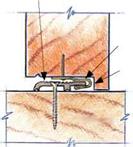

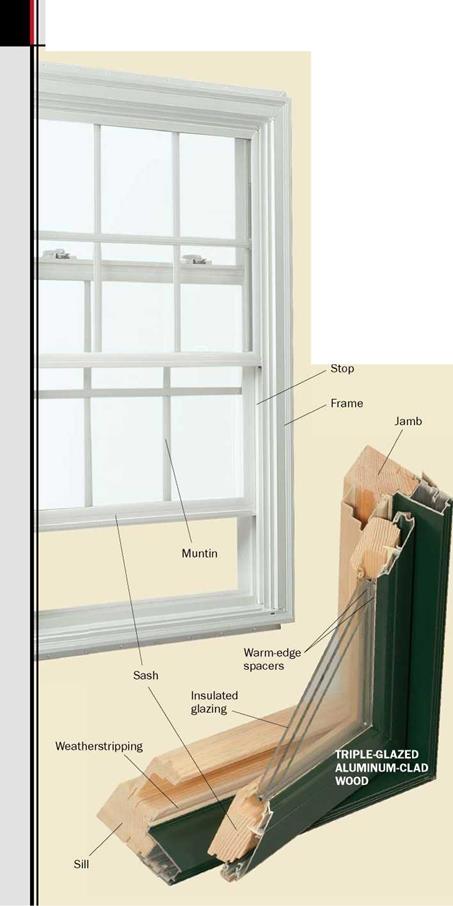

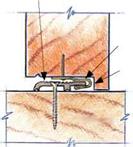

Spacers Are Potential Weak Points

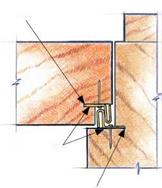

Spacers between glass panes perform three functions: They maintain a uniform separation between pieces of glass, they provide a good adhesive surface for the glass, and they create an airtight seal for the insulating cavity.

Although you should choose windows based on their overall performance ratings, the spacer, while small, substantially impacts a window’s U-factor and condensation resistance.

The spacer’s job is complicated by the fact that it’s in contact with both the inside and outside surfaces of the window, forming a bridge between indoor and outdoor environments. Because the spacer is more conductive than the air or gas fill, it changes the temperature of a 21/2-in.-wide band around the edge of the glass. As a consequence, the window’s overall U-factor is affected. In smaller windows, the 21/2-in. temperature band is a larger percentage of the window and has a greater effect on the window’s U-factor. While spacers can be considered the Achilles’ heel of all windows, a casement window performs slightly better than a double-hung of the same size because the former has less spacer area. Likewise, the thermal performance of true divided-lite windows made up of multiple IG units suffers because of all the spacer area in the window. (Simulated divided lites can also affect U-factor if the grille creates a thermal bridge between the panes.)

Spacers are made of aluminum, steel, fiberglass, foam, and thermoplastics, often in some combination. Foam spacers have the lowest U-factor, while aluminum has the highest. Today, quality windows use "warm – edge" spacers. (It’s worth noting that warm – edge means only that it’s less conductive than aluminum.) A good warm-edge spacer raises the interior surface temperature of the glass along the perimeter of the window.

This is especially important at the window’s

bottom edge, which is most subject to condensation. At 0°F outside, a good spacer increases the temperature at the bottom of the inside glass pane by 6°F to 8°F. As a result, a more comfortable relative-humidity level indoors is possible during the winter without window condensation. bottom edge, which is most subject to condensation. At 0°F outside, a good spacer increases the temperature at the bottom of the inside glass pane by 6°F to 8°F. As a result, a more comfortable relative-humidity level indoors is possible during the winter without window condensation.

Posted by admin on 18/ 11/ 15

When most people choose windows, they begin by considering the frame material. They might be predisposed to traditional wood or low-maintenance vinyl. However, according to Nils Petermann at the Efficient Windows Collaborative, the most important factor to consider is the frame’s durability. This is where I’d like to refer you to an independent organization that provides unbiased durability ratings for window frames. Unfortunately, there isn’t one.

You can make educated guesses about durability based on the frame material. But whether it’s wood, vinyl, fiberglass, aluminum, clad, or composite, a well-constructed window lasts longer and performs better than a poorly constructed one regardless of the relative benefits of its frame material.

The best way to get a sense of window quality is to read all the product literature you can get your hands on and to look at actual windows—a lot of them. Go to the big-box store and the local building supply, and open and close the windows on display, paying attention to how the corners are joined, how well the sashes seal, and how rigid the unit is.

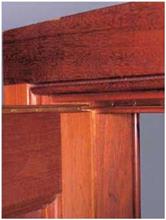

On vinyl windows, look for continuous thermally welded corners. Examine the corner cutaway displays of aluminum windows for a continuous thermal break in both frame and sash. On a clad window, the cladding should have well-sealed corners and gaskets to prevent water from getting behind the cladding. Aluminum is an excellent heat conductor, so be sure that aluminum cladding doesn’t contact conditioned interior air at any point.

Another way to sift through the options is to talk to reputable builders and architects in your area. Ask what windows they use and how long they have been using them. They won’t stick with windows that make their clients unhappy.

Thirty years ago, when single-pane windows were the rule rather than the exception, companies looking to improve window performance focused their research on insulating glass. It was the lowest-hanging fruit. They’ve done such a good job that the R-value of insulated glass is good enough to make the window frame the weak link in the thermal chain. That’s one reason why manufacturers list performance data for relatively large windows, say, 4 ft. by 5 ft. (When you’re comparing windows, make sure the performance data are for windows of the same size.) Windows with large areas of glass yield better performance numbers because the frame is a smaller percentage of the window area. Savvy window designers understand this and tweak their windows accordingly for optimal performance. By using strong materials that permit low-profile sills, sashes, and jambs, they minimize the size of

To understand and appreciate how a window works, To understand and appreciate how a window works,

■ you need to know the components that make up a basic window. While there are several types of windows besides the double-hung and casement illustrated here, the terminology used to describe each piece is universal.

Windows need to insulate

Sealed airspaces improve insulation. The more insulating spaces in the glass unit, the better the performance; tripleglazed windows are among the most energy efficient you can buy. Aluminum, vinyl, and fiberglass frames use extruded chambers both for strength and as a thermal break. Filling these cavities with foam provides additional insulation. Solid-wood frames are about as efficient as vinyl.

Window DNA: The NFRC Label by the Numbers

U-FACTOR

A measure of the insulating value. U-factor is the nonsolar heat flow through all parts of the window (glass, frame, and sash).

A lower number means better insulation and greater performance.

visiBLE TRANSMiTTANCE (vT)

A measure of the amount of visible light that passes through the window. Values range from 0 to 1 (a higher number equals more light). However, most ratings are between 0.3 and 0.8 because they take into account the light blocked by the frame. Choose windows with higher VT to maximize daylight and views.

CoNDENsAHoN RESiSTANCE

A relative scale from 0 to 100 — based on the window’s properties. It predicts the likelihood of condensation, with higher numbers indicating less condensation.

the conductive frame while being sure to incorporate materials that reduce air leakage.

Frame material can also influence how long a window stays airtight. Like most building materials, windows expand and contract with changes in temperature and humidity. When you see a window with moisture between panes, it’s likely that movement between the glass and the sash broke the insulating seal. By choosing stable materials, you can reduce stress on the seal and increase the window’s longevity. Fiberglass expands at the rate of glass, while aluminum and vinyl expand respectively 3 times and 7 times more than glass. Wood moves in response to humidity changes rather than temperature.

Posted by admin on 17/ 11/ 15

■ BY SEAN GROOM

hen you roll up to a house for the first time, you can’t help but notice the windows. Their size, style, and placement determine if they’re appropriate to the architectural style and, to some degree, if the house will be a pleasure to be in.

For most people, that’s as much thought as they give to windows. And that’s too bad, because picking the right windows can lower heating and/or cooling costs, improve comfort inside the house, and improve indoor-air quality by dramatically limiting condensation.

To buy the best-performing windows for your house, though, you need to know a bit about how they work and what they need to do.

A Window Has Four Basic Jobs

The first thing a window has to do is control heat gain and loss. Technically, these temperature changes take place through conduction, convection, and radiation. As a practical matter, these temperature changes affect your comfort. If you’re sitting next to a window, you’ll experience conduction and convection when the glass acts as a cold radiator in the winter; and you’ll experience

radiation on a sunny day when you feel like an ant trapped under a magnifying glass.

Second, a window must control solar – heat gain. I say control because heat gain isn’t always bad. If you live in a heating climate—generally speaking, anywhere north of Oklahoma with the exception of California—you should take advantage of the free heat windows can provide.

Third, windows need to regulate airflow. They should be airtight when closed and also offer fresh air when you want it.

Finally, windows provide natural light and frame views both near and far.

Frame Materials Dictate Performance, Maintenance, and Cost

Aluminum Aluminum frames are strong, durable, inexpensive, and require little maintenance. Aluminum is highly conductive, however, leading to heat loss. To achieve even modest insulating levels, the frame and sashes must be carefully engineered with thermal breaks. Even then, they are best in mild desert climates or on impact – resistant windows in hurricane zones.

Wood The only choice for some traditionalists, wood offers a pick of colors (and it can be changed later on). Wood frames are moderately priced and have good insulating value and structural strength, but they’re not low maintenance; they require periodic cleaning and painting, which adds to their overall cost.

Clad Windows with aluminum-, vinyl-, or fiberglass-clad wood frames are the most expensive. A clad unit offers the low – maintenance durability of aluminum, vinyl, or fiberglass on the outside and the thermal resistance and appeal of wood on the inside. Well-engineered aluminum clad

ding should strengthen the window. Custom colors for aluminum cladding can match any paint chip at an additional cost.

Vinyl Vinyl frames are formed of extruded PVC. Multiple chambers in the frames and sashes add rigidity. These chambers also act as insulation in the same way as the airspace between glass panes; some manufacturers fill the chambers with foam insulation to improve the frame’s insulating ability.

Vinyl is available in only a few colors, generally white and some variation on almond. Darker colors absorb too much heat, causing vinyl to deform and degrade. It’s typically the least expensive window.

Fiberglass The best you can get if you want to maximize a frame’s insulating ability, fiberglass is the least conductive material, and the frame can be insulated with foam. More expensive than aluminum, vinyl, or wood, fiberglass requires little maintenance and is durable and extremely strong. It can be extruded in low-profile frames and sashes in several colors and is paintable. Another advantage is that as the temperature changes, fiberglass expands and contracts at a rate almost identical to the glass. This helps to prevent seals along the glass from failing.

Composite Composite windows, like composite decking, are made of wood fibers (sawdust) mixed with vinyl resins. Up to 40 percent of the window content is recycled. Most, if not all, composite windows are sold as replacements by the Renewal By Andersen® division of Andersen® Windows. The material’s tradename is Fibrex®. It looks a lot like wood, will not rot, requires little maintenance, and can be stained on the inside.

Posted by admin on 17/ 11/ 15

Interlocking metal weatherstripping is an efficient way to seal air leaks around doors. It comes with two different pieces; one attaches to the door, and the other to the jamb and the threshold. When closed, the two pieces interlock to form a seal. This type of weatherstripping is the most difficult to install, a job best left to pros. If your doors already have interlocking metal weather-

|

stripping, keep it working smoothly by straightening any bends or dents that prevent the two pieces from fitting together.

|

|

|

|

Durability: excellent Cost: $1.50/ft. to $3/ft.

|

|

|

HINGE SIDE

|

|

|

|

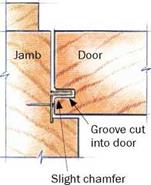

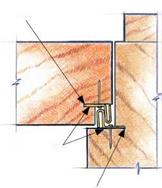

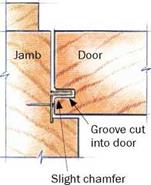

On the hinge side of the door, a bronze strip nailed to the jamb slips into a groove cut in the door.

|

|

|

LATCH SIDE AND TOP

Saw kerf

|

|

|

|

|

|

|

Interlocking bronze strips

|

|

|

Aluminum with vinyl top and feet

|

|

|

|

|

On the head and latch sides, bronze strips let into saw kerfs and nailed on both the door and the jamb interlock.

|

|

|

Adjustable – height oak and aluminum

|

|

|

|

|

|

|

|

Vinyl top on

paintable

hardwood

|

|

|

|

|

aluminum with vinyl top in bronze finish

|

|

|

At the door bottom, a bronze hook strip on the door engages the saddle screwed to the sill.

|

|

|

Durability: Excellent Cost: $3.85/ft. to $7/ft.

|

|

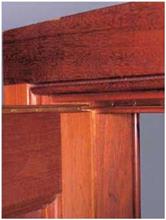

however, should be outfitted with a threshold designed to shed water away from the house. If an existing wooden threshold shows signs of water damage, simply replacing it will only postpone a larger problem.

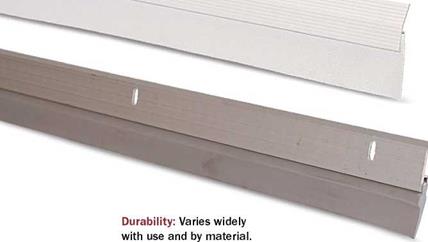

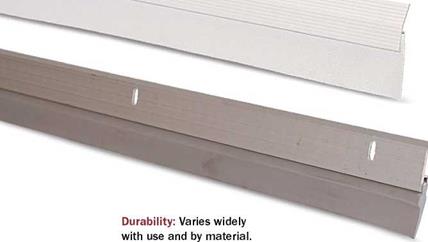

Door Sweeps

Installing a door sweep is the final step in sealing air leaks under a door. Sweeps come in various styles, one of which simply attaches to the outside of a door. Metal, vinyl, or wood versions connected to either felt or foam all can be cut to length with a hacksaw, backsaw, or tin snips, and most simply screw to the bottom of a door. When trimming the sweep, cut it about V8 in. shy of the overall door width. Some versions are nailed instead of screwed into place. If possible, opt for a version that screws into place through elongated holes because they allow for easy adjustment.

Other sweep styles actually wrap the bottom of the door and rely on a rubber or foam gasket along the door’s bottom edge to seal tight against the threshold. Again, look for a model with elongated screw holes that enable you to adjust the sweep. You might have to remove the door to mount the sweep.

Automatic door sweeps are a fairly recent invention, and they come in handy if the door opens over irregular stone or carpeted floors, where a regular sweep would drag or bind. With automatic door sweeps, a vinyl flap drops down to seal leaks when the door is shut, but retracts when the door is open. If it sounds like hoodoo, it’s not: A stop button attached to the jamb lifts and closes the flap.

Matthew Teague is a furniture maker and journalist in Nashville, Tenn.

|

|

|

|

|

White and brushed chrome with adjustable screw holes

|

|

|

Cost: ЗЗФ/ft. to $3.30/ft.

|

|

Posted by admin on 17/ 11/ 15

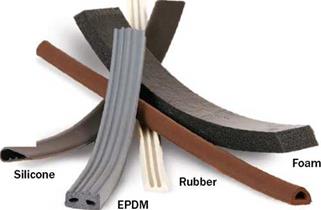

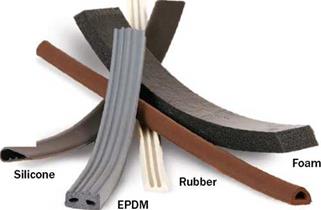

These inexpensive tapes come in several varieties: nonporous, closed-cell foam; open-cell foam silicone; and various rubbers, including a product called EPDM (ethylene propylene diene monomer). It’s worth spending a few extra cents per foot to buy the more-efficient closed-cell foam or higher-quality silicones. Any of these styles can be purchased in various thicknesses and lengths.

Although installation is easy—little more than peel-and-stick—be sure to clean surfaces using a mild detergent prior to setting the tape in place. In areas that see little use, such as inoperable windows, expect the tape to last roughly three years. On frequently opened windows, you’ll need to replace it in as little as a year. Securing the tape with tacks or staples helps to extend its longevity. As a general rule, apply this type of weatherstripping only on parts of windows that are not opened, such as around the upper sash.

Durability: Poor Cost: Vinyl foam: about 20ФДк X-Treme Rubber: about ЗОФ/ft. Rubber foam: about ЗОФ/ft. EPDM rubber: about 80ФДк Silicone: about $1.15/ft.

|

|

|

|

|

Available at tool-rental outlets, this laminate trimmer has a 45-degree angled base that slides between the window jamb and stop to cut an angled groove for silicone-bead and other kerf-in weatherstripping.

|

|

|

OPTIONS FOR AN EXTERIOR DOOR

The swinging motion of a door allows you a greater choice of weatherstripping. In most cases, though, you must pay attention to how it should be applied. Some types of weatherstripping attach to the door jamb, and others to the doorstop.

|

|

|

TOP OF

DOOR

V-strips

(attach to jamb)

Felt

(against doorstop) Tapes

(attach to doorstop)

Rigid jamb

(attaches to jamb and abuts doorstop) Kerf-in (against doorstop)

HINGE SIDE OF DOOR V-strips

(attach to jamb)

Felt

(applied to jamb) Tapes

(applied to jamb) Kerf-in

(against doorstop)

|

|

|

LOCK SIDE OF DOOR V-strips (attach to jamb; notch to fit around latch plate)

Felt (against doorstop; place separate lengths on each side of latch plate)

Tapes (abut doorstop)

Rigid jamb

(attaches to inside face of doorstop)

Kerf-in (against doorstop)

BOTTOM OF DOOR

Vinyl, metal, or wood thresholds Door seals, sweeps, or shoes; attachment varies by style

|

|

Cut the groove toward the corners. Plunge the kerfing tool into the seam between the window jamb and the stop that holds the sash, and move it slowly toward the top and bottom corners of the jamb. A vacuum hose sucks up stray sawdust. silicone-bead and other kerf – in weatherstripping is easy to install. Just cut the corners at a 45-degree angle, and press the flat fin into the kerf. Cut the groove toward the corners. Plunge the kerfing tool into the seam between the window jamb and the stop that holds the sash, and move it slowly toward the top and bottom corners of the jamb. A vacuum hose sucks up stray sawdust. silicone-bead and other kerf – in weatherstripping is easy to install. Just cut the corners at a 45-degree angle, and press the flat fin into the kerf.

Durability: silicone: excellent Plastic polymer and foam: good Cost: Plastic polymer: about 18$/ft. Foam: about 38$/ft.

Silicone: 35$/ft. to $1.10/ft.

Kerf-In

A kerf is a blade-width notch cut into a door or window jamb with a saw or router. New doors often come with kerf-in weatherstripping in place. Although silicone might last up to 50 years, plastic and foam kerf-in weatherstripping might need replacement sooner. Simply pull out the old weatherstripping and snap the new, self-locking product into place.

Although it’s possible to install kerf – in weatherstripping on old windows not originally designed for it, you need to rent a corner-grooving tool (see the photos above left and on p. 87) to create the kerf. If you’re tool savvy, these router-like machines are easy to use. Expect to pay about $70 per day for the rental.

Posted by admin on 17/ 11/ 15

■ BY MATTHEW TEAGUE ■ BY MATTHEW TEAGUE

ver time, houses settle, doors sag, and weatherstripping wears out, creating small cracks around windows and doors. These leaks can account for 20% to 40% of a home’s heat loss. As warm air escapes in winter (and cool air in summer), the good money you’ve paid for heating (or airconditioning) disappears, too.

Various contractors can bring in high – tech detectors to determine where your house is losing heat, but doing a close inspection on your own reveals more trouble spots than you might imagine. Adding or replacing weatherstripping around windows and doors as well as sealing door bottoms are the obvious remedies to start with.

Many types of weatherstripping are available at your local home center or hardware store. You can install several products easily without specialized tools; others are more difficult to install but can give you much longer service. This survey covers the range of weatherstripping products you’re likely to find at a local home center and provides you with the information you need to weigh cost, life expectancy, insulating efficiency, and installation effort.

Rigid Jamb

This type of weatherstripping consists of a metal or vinyl flange attached to a tubular section of either hollow vinyl or rubber. Tubular sections on higher-quality versions are filled with silicone or foam, which provides better insulation and allows the weatherstripping to hold its shape over time.

The flange is nailed, stapled, or screwed to the jamb, and the tubular section compresses to seal the openings. This product can be installed on either doors or windows: Simply close the window or door, butt the tubular section against it, and attach the flange to the jamb. Choose rigid-jamb styles that are adjustable; they usually have elongated holes for fasteners. Don’t paint the tubular sections because that reduces their flexibility and efficiency.

Vinyl Vinyl

V-Strips

Sold in rolls, this flexible V-shaped weatherstripping compresses to seal gaps inside the tracks on windows and doors. V-strips come in bronze, vinyl, stainless steel, copper, and aluminum. One advantage of V-strips is that they disappear into the tracks of windows and doors. Adhesive-backed V-strips are the easiest to install.

Metal V-strips hold up better than the vinyl versions but are trickier to install. The ends of mating pieces must be cut (using tin snips) for a tight fit, and driving brads every 3 in. amounts to a lot of hammering. (Use a nailset for the last taps on the brads.) To prevent the leaves from overlapping at the corners, trim the leaves at an angle. Metal V-strips are quite durable; as they age and compress, run a putty knife, nailset, or screwdriver down the inside of the crease to extend their life.

One caveat: If doors and windows already fit tightly, adding springy V-strips in the tracks will make them harder to open and close. On both windows and doors, you need to trim away parts of the weatherstripping to accommodate locks and pulley mechanisms.

Felt

Felt weatherstripping can be purchased in rolls of various thicknesses, widths, and colors. It comes in either pressure – sensitive or nail-on versions; some are adhered to a flexible vinyl or metal backing. The increased rigidity of the metal (or, to a lesser extent, vinyl) improves felt’s efficiency.

Wool felt is the most durable. However, because

felt can snag on splinters or catch between sliding parts, it tends to wear out quickly on operable windows and doors. In areas prone to moisture, avoid using felt altogether. Although it’s easy to install (and was the standard 50 years ago), felt is relatively inefficient compared to other weatherstripping products now on the market.

| |

A window’s U-factor is the inverse of its R-value; the lower the U-factor, the better the window is at resisting heat flow. A low U-factor is desirable in all climates. While the best double-glazed windows have a U-factor of about 0.27, triple-glazed windows have U-factors as low as 0.17.

A window’s U-factor is the inverse of its R-value; the lower the U-factor, the better the window is at resisting heat flow. A low U-factor is desirable in all climates. While the best double-glazed windows have a U-factor of about 0.27, triple-glazed windows have U-factors as low as 0.17.

freelance writer in Bloomfield, Conn.

freelance writer in Bloomfield, Conn.

Impact-Resistant Glass Offers Protection

Impact-Resistant Glass Offers Protection

ing decisions should be based on this number, which appears on the NFRC label (above).

ing decisions should be based on this number, which appears on the NFRC label (above). bottom edge, which is most subject to condensation. At 0°F outside, a good spacer increases the temperature at the bottom of the inside glass pane by 6°F to 8°F. As a result, a more comfortable relative-humidity level indoors is possible during the winter without window condensation.

bottom edge, which is most subject to condensation. At 0°F outside, a good spacer increases the temperature at the bottom of the inside glass pane by 6°F to 8°F. As a result, a more comfortable relative-humidity level indoors is possible during the winter without window condensation.

To understand and appreciate how a window works,

To understand and appreciate how a window works,

Cut the groove toward the corners. Plunge the kerfing tool into the seam between the window jamb and the stop that holds the sash, and move it slowly toward the top and bottom corners of the jamb. A vacuum hose sucks up stray sawdust. silicone-bead and other kerf – in weatherstripping is easy to install. Just cut the corners at a 45-degree angle, and press the flat fin into the kerf.

Cut the groove toward the corners. Plunge the kerfing tool into the seam between the window jamb and the stop that holds the sash, and move it slowly toward the top and bottom corners of the jamb. A vacuum hose sucks up stray sawdust. silicone-bead and other kerf – in weatherstripping is easy to install. Just cut the corners at a 45-degree angle, and press the flat fin into the kerf.

■ BY MATTHEW TEAGUE

■ BY MATTHEW TEAGUE

Vinyl

Vinyl