Longitudinal Porosity behind the Center of the Paver

Figure 11.21 schematically represents a phenomenon caused by the improper distribution of a mixture with augers. The distribution of a mixture along a paver screed should be checked. If the mixture is not properly distributed across the full width of the paver screed, streaks of porosity may become obvious. Another cause may be the location of the augers’ driving unit (gear box) in the middle of its width.

11.8.2.2 Longitudinal porosity (off center)

Longitudinal porosity parallel to the direction of spreading but not centered behind the paver appears fairly often (Figures 11.22 through 11.24). It may be caused by either of the following:

Longitudinal porosity parallel to the direction of spreading but not centered behind the paver appears fairly often (Figures 11.22 through 11.24). It may be caused by either of the following:

|

|

|

|

|

|

|

|

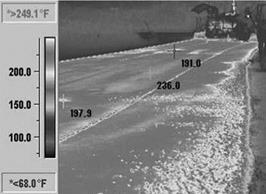

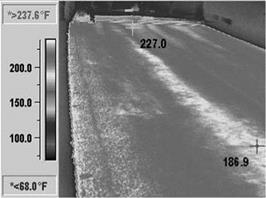

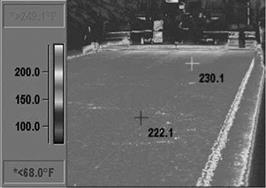

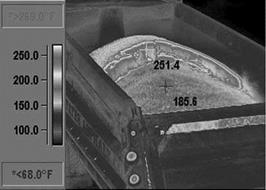

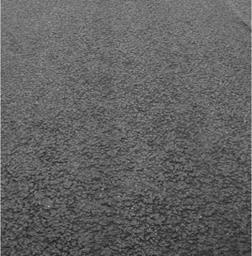

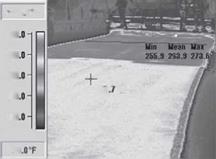

FIGURE 11.22 Longitudinal porosity off the center of the paver. |

|

FIGURE 11.23 Examples of drop in mixture temperature due to longitudinal porosity in the spread lane. (Photo courtesy of Kim A. Willoughby, WSDOT, United States.) |

|

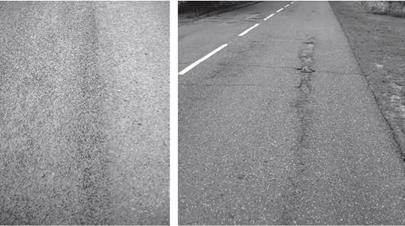

(a) (b)

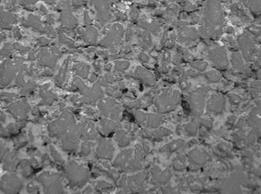

FIGURE 11.24 Longitudinal porosity: (a) on a new SMA pavement and (b) pavement damage in a porous area. (Photos courtesy of Krzysztof Blazejowski.) |

11.8.2.3 Porosity in Other Distinctive Places

Porosity may also be found as follows on an SMA course:

• At the beginning or end of a work site

• In irregularly shaped spots

• At the edge of a compacted course

Porous spots (areas) occur fairly frequently at the beginning or end of a work site when spreading an SMA (or other asphalt mixture) course. This chiefly results from some difficulties with the correct start of laying by a paver (sometimes called take off). Because the beginning of a work site cannot be cut off and removed, such areas of porosity appear mostly at the beginning of a spreading shift (Figure 11.25).

A similar result happens with the manual spreading of mixtures for some length at the beginning of paving followed by compacting with rollers. Manual work cannot equal the efficiency of placement with a paver, which provides more than 80% of the initial compaction. The effect is evident—the course in that area is uncompacted and uneven. Other places that were manually placed because there was no room for a paver look similar (Figure 11.26).

As mentioned before, pockets of porosity appear cyclically now and then (Figures 11.27 and 11.28). Their cause is not easy to explain. Maybe the paver was setup incorrectly or, more frequently, perhaps there were pieces of cool mixture in the SMA or segregation was still occurring in that stage of mixture production. Or the cause may be something entirely different and difficult to determine.