FINISHING THE LAYER

Some countries require special finishing techniques for SMA surfaces. Those requirements are described here.

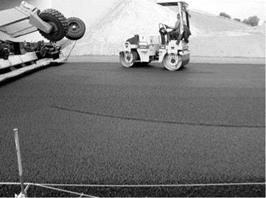

Applying a layer of grit to the finished surface is often specified. Why has gritting been applied? Soon after placement, the SMA layer is characterized by relatively low friction (the so-called postconstruction slipperiness) caused by a thick film of binder on particles of aggregate. Spreading additional aggregate on the surface of the hot SMA, followed by rolling (to embed the grits) is aimed at breaking the binder film on the coarse particles. Due to its microtexture, well-embedded grit breaks the water film, hence increases the skid resistance of SMA.

Without gritting, the process of rubbing the binder film off the aggregate particles that provide the SMA macrotexture proceeds slowly under the action of traffic, first in the wheel paths, and then, after some time, all over the roadway surface. This pattern of wear brings about the development of nonuniform friction characteristics of the wearing course. Dutch researchers (Jacobs and Fafie, 2004) have demonstrated low values of friction coefficients appearing on both a dry and a wet SMA course:

• On a dry pavement in summer, the binder film on the surface of the aggregate particles softens at high temperature, changing the binder film into a lubricant, reducing the friction between tires and aggregate particles.

• On a wet pavement, because of the thick binder coat, the aggregate microtexture is not able to break a water film on the surface of an SMA course.

If the SMA contains a PMB, the binder film remains intact for a longer period of time.

Therefore some additional solutions for enhancing the friction coefficient should be applied to increase the friction in the early stages of trafficking the roadway while the binder film remains intact. Some observations prove that it might take as long as 6 months to rub off the binder film on the coarse particles.