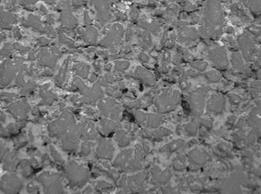

TOO POROUS SMA STRUCTURE

Just as it is possible to find an SMA course that is too closed, so too it is possible to find a course that has too high a void content. This problem may occur over very large areas, which are marked by excessive porosity. Local porosity over smaller areas, is described in Sections 11.8.2.3 through 11.8.2.9.

The issue of how open the SMA structure should be has been debated for some time. True enough, we happen to find a quite porous SMA structure every now and then. An investor or may owner sometimes agrees to leave in place an SMA that is too closed (after an antiskid treatment); unfortunately an SMA that is too open more often falls victim to a road-milling machine. An open structure (Figure 11.9) of a mixture consisting of lots of mutually connected pores is conducive to water and air penetration (see Chapter 12), which results in a shorter service life of the course.

An excessively open structure of an SMA course may be caused by any of the following: [67]

|

FIGURE 11.9 A close-up of an SMA course surface with a high content of voids. (Photo courtesy of Krzysztof Blazejowski.) |

High contents of free voids in a compacted SMA course may result from a mistake made while designing the mixture. Usually the cause is a result of one of the following:

• An undue shifting of the grain size curve to the right and an increase of the coarse aggregate fraction to greater than 80%, with a simultaneous decrease in both the sand fraction and the filler, plus a reduced content of binder—as we remember, an increased amount of material on the 2.0 mm sieve requires an increase in the binder content to fill the voids of an SMA mixture

• A reduction of SMA binder contents, sometimes practiced for the sake of economy

• The application of excessive temperatures and increased energy during the compaction of samples in the laboratory,* resulting in an incorrect mixture design.

If porosity appears over larger areas and is not an error of composition, one may expect that the number of rollers or passes have not been suitably selected or that too cool a mixture has been spread. Sometimes the difference may be noticed when watching the layout structure of aggregate grains. Grains of a mixture spread at too low a temperature look as if they have been pulled by the paver screed; they are not arranged tightly side by side (Figure 11.10).

Leave a reply