Creep Tests

Encouraging results of SMA resistance to deformation are being confirmed both in laboratory tests and on trial sections of pavements in operation. Clearly, in the majority of cases an SMA mixture is actually better than asphalt concrete (AC). Conversely, not every test method confirms that SMA possesses the better characteristics. The outcome depends on the loading mode and conditions of testing. The SMA tests resulting in divergent outcomes include

• Uniaxial creep test with a constant load (also called static creep), unconfined

• Uniaxial creep test with a repeated mode of loading (also called dynamic creep or repeated load axial test [RLAT]), unconfined

The classic versions of both tests have been carried out on 100 mm diameter specimens with a 100 mm loading platen (the so-called variant 100/100).

Figure 12.1 shows the mode of loading a 100 mm diameter cylindrical specimen with a 100 mm diameter platen. The whole top face of the cylinder is being loaded in an unconfined conditions (i. e., with no side support). Bearing in mind Figure 2.3, it is obvious that the power of an SMA structure also depends on the strength of the side support (Said et al., 2000). There is no such support in an unconfined creep test and loading the sample’s entire cross-sectional area. That is why, when testing SMA with this test, the results may suggest that SMA is a worse mixture than an AC mixture which has an aggregate mix characterized by a different type of particle interlocking. The fundamental assumptions of creep testing with no side support have been criticized for a long time (e. g., in Ulmgren, 1996). In spite of this, a large number of test results based on unconfined creep testing may be found in many publications.

The same tests with a different sample loading system produce different comparative results between AC and SMA. The following are two other creep tests that incorporate side support:

• Uniaxial creep test with a repeated mode of load with side support (also called indentation repeated load axial test [IRLAT])—variant 100/150

• Uniaxial creep test with a repeated mode of load with vacuum confinement (also called vacuum repeated load axial test [VRLAT]; see also triaxial test).

|

If a 100 mm diameter cylindrical specimen is replaced by a larger one (i. e., with one that has a 150 mm diameter [Figure 12.2]) and the loading plate has a diameter of 100 mm, then the loaded area of the specimen will be laterally supported. The

|

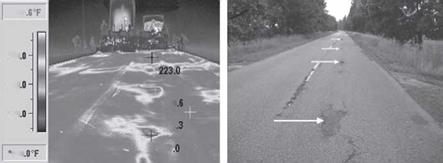

FIGURE 12.1 Creep test with no side support, variant 100/100: (a) test scheme and (b) testing in Nottingham Asphalt Tester. (Photo courtesy of Krzysztof BlaZejowski.)

loading scheme (variant 100/150) and test results are, in this instance, closer to the real performance of a pavement on a road. In many countries, a modified creep test with a repeated mode of load (IRLAT or VRLAT) has been adopted for an assessment of the resistance to deformation of mixtures. Consequently, proper correlations between results of creep tests and wheel-tracking tests have been developed (Said et al., 2000; Ulmgren, 1996).

It is worth knowing that there is a substantial difference between the results of static creep tests of cylindrical specimens compacted in a laboratory for design purposes and specimens cut out of a finished course. Despite having the same composition and similar densities, specimens cut out of a course are characterized by lower values of the creep modulus than Marshall and gyratory compacted specimens prepared in a laboratory (Renken, 2000).

According to the standard EN 13108-20, static and dynamic creep tests do not apply to SMA. The cyclical compression test (100/150—IRLAT) has been described in EN 12697-25 as method A, with test parameters as follows:

• Square loading pulse

• Frequency of 0.5 Hz (load 1 sec, rest period 1 sec)

• Load of 100 ± 2 kPa

• Typical test temperature of 40°C

• Total test duration of 3600 cycles (2 hours)

215

215