Continuous Porosity by the Edge

This defect appears in a continuous way along the edge of a layer (Figures 11.17 and 11.18). It is mainly brought about by the following:

|

FIGuRE 11.13 Formation of streaks or mixture pulling due to incorrect setup of paver screed segments. |

|

FIGuRE 11.14 The effects of an incorrect paver setup, temperature in degrees Fahrenheit. (Photo courtesy of Kim A. Willoughby, WSDOT, United States.) |

|

FIGuRE 11.15 Area of an uncompacted cool mixture during a paver standstill (a zone of cooling mixture that is inaccessible to rollers). |

|

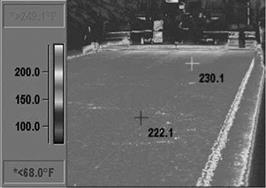

FIGURE 11.16 Paver standstills and their effects—infrared images. (Photos courtesy of Kim A. Willoughby, WSDOT, United States.)

• Badly adjusted mechanism of mixture distribution through the augers or improper operation of the augers (insufficient quantity of a mixture supplied to the screed edge)

• Length of augers too short in comparison with the board width (several board segments with no additional feeding segments applied)

The porosity of a layer is usually easily seen when the surface is wet (Figure 11.18.b). Another problem (less often observed) can be caused by manual raking of a mixture along the edges of a spread lane (Figures 11.19 and 11.20). Unfortunately, leveling a newly spread mixture with rakes or shovels is the customary manner of some paver teams. Manual raking cannot produce the same level of uniformity as mechanical leveling, leading to cooler portions and porous areas in the mat.

Leave a reply