Production process

Suppose that we have already developed the job mix formula and that well-performing batching devices, a screen deck, balances, and so on are at our disposal. Then we are ready to start production. A common occurrence with starting up an asphalt plant is the instability of the mixture temperature during the first production period. Therefore one should take into account that some batches will be underheated, while others will be slightly overheated. Such waste material should be rejected.

9.3.1 SMA Production Temperature

Two components of an SMA mixture must be heated—the aggregate and the binder. This heating is aimed at (1) eliminating moisture from the aggregate to a level that enables the proper coating of the aggregate grains and (2) maintaining the appropriate temperature of the mixture delivered to the laydown site, which allows for its proper placement and compaction. The coating temperature is directly related to the viscosity of the chosen binder. The harder the binder or the more highly modified the binder is, the higher the production temperature must be. That is why the SMA production temperature is most often specified as a function of the type of binder.

The SMA production temperature has been diversely defined in different countries in the following manner: [56]

reveal data and ensure substantially uniform conditions for SMA production; EN standard 13108-5 (which applies only to unmodified binder) is a good example of such a document.

• Variant 2—the manufacturer of the binder discloses information on the recommended production temperature; this method has been used for modified and special binders.

• Variant 3—the viscosity range of the binder is used as the basis for the independent determination of the production temperature; in this case the viscosity-temperature relationship should be defined to allow determination of the range of temperatures that produces the needed binder viscosity.

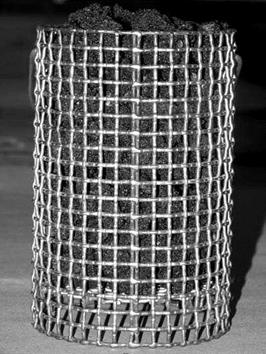

An overview of SMA production temperatures according to selected documents is displayed in Table 9.1. A wide range of temperatures is specified in this table. One should remember that each increase of the mixing temperature enhances the risk of binder-mastic draining off the aggregate while also increasing the binder aging. The classic draindown test with Schellenberg’s method is carried out at 170°C, producing incomplete information about its behavior at higher temperatures. That is why it is a good idea to conduct another draindown test at a higher temperature that reflects the possible SMA production temperature (see Chapter 8).

Test three samples of the same mix with the same binder content.

Test three samples of the same mix with the same binder content. (W – W – W4)

(W – W – W4)