Due to the resistance to compaction provided by the coarse aggregate skeleton, SMA mixtures can cause problems during laydown. Thus in almost all countries that have adopted SMA, some additional requirements on conditions at the work site must be observed, including the appropriate temperature, wind velocity, and the absence of rain.

10.2.1 Minimum Temperature of Air and Underlying Layer

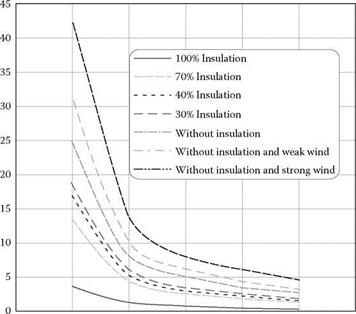

To ensure that weather conditions are acceptable during laydown, the air temperature may be checked often. In many countries, however, air temperature is not as important as the temperature of the course on which the hot mixture is going to be placed. Required laydown conditions frequently hinge on the thickness of the constructed layer, because thick layers cool more slowly, and on the type of binder used, whether modified or unmodified.

Two types of weather conditions may be distinguished in specifications: conditions at the time of laying and conditions within 24 hours prior to starting work. Average requirements for the minimum air temperature at the time of placing an SMA mixture range from 5°C to 10°C as exemplified by the following:

• German Dav documents stipulate an air temperature of not less than +5°C (Milster et al., 2004)

• The Czech standard CSN 736121 requires +5°C.

• The Polish guidelines WT2 2008 specify +10°C for courses less than 3 cm thick and +5°C for courses greater than or equal to 3 cm thick.

• The Australian NAS AAPA 2004 calls for +5°C, with the limitation that laying courses thinner than 4 cm or containing a modified binder should be avoided at such low temperatures.

In general, the temperature requirements are becoming stricter (increased) in cases where the thickness of a course is less than 40 mm; for that thickness, a minimum requirement of +10°C is commonly specified. In Germany’s ZTV Asphalt-StB 07, the weather limitations for SMA laying are as follows:

• When the course thickness is less than 3 cm, the minimum air temperature is +10°C, and the minimum sublayer temperature is +5°C.

• When the course thickness is more than 3 cm, the minimum air temperature is 5°C.

The average requirements for the specified underlying layer’s temperatures are similar and are also within a range of 5-10°C. A higher value is often used for mixtures with modified binder. Another document, the U. S. Federal Aviation Administration Advisory Circular 150/5370-10B on civil airfields, has stipulated the following minimum temperatures of the underlying course during laydown, which depend on the thickness of the asphalt course being placed:

• For a course less than 2.5 cm thick, the underlying layer temperature must not be lower than 10°C.

• For a course 2.5-7.5 cm thick, the underlying layer temperature must not be lower than 7°C.

• For a course greater than 7.5 cm thick, the underlying layer temperature must not be lower than 4°C

Slightly lower values than those just cited have been adopted when specifying temperatures during the day directly preceding the start of laying down the hot mixture. For example, according to the Czech standard CSN 73 6121, the air temperature must be no less than 3°C (5°C for a thin course), and according to the Polish guidelines WT2 2008, it must be at least 0°C (5°C for a thin course).

Another, indirect method of specifying temperature requirements is by limiting the permissible calendar period of SMA laydown—for example, by imposing a ban on works over a specified period of the year (e. g., between October 15 and March 15).

Finally, it is worth noting that a bituminous mixture with an unmodified binder can be laid down at a temperature slightly lower than a bituminous mixture with a modified binder.

FIGURE 10.8 PMB tape for sealing pavement joints (a) when bonding with a layer edge and (b) after application. (Photos courtesy of Slaskie Kruszywa Naturalne sp. z o. o., Poland.)

FIGURE 10.8 PMB tape for sealing pavement joints (a) when bonding with a layer edge and (b) after application. (Photos courtesy of Slaskie Kruszywa Naturalne sp. z o. o., Poland.)