Method after AASHTO T 305-97

The U. S. method of mastic draindown testing has been described in the standard AASHTO T 305-97. It is used for porous asphalt mixes (also called open-graded friction course [OGFC]) and SMA mixes. Test parameters are shown in Table 8.2.

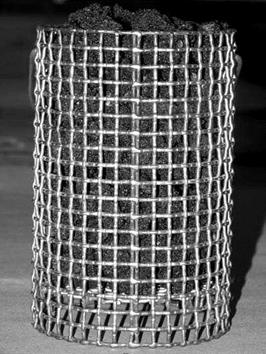

Samples of the mix are placed in wire baskets (Figure 8.3). For SMA mixes equal to and larger than 9.5 mm maximum aggregate size, the basket should have

6.3 mm holes in the mesh, and for 0/4.75 mm SMA mixes, the holes should be 2.36 mm.

8.2.3 Methods after EN 12697-18

The two methods of draindown testing that are given in the European standard EN 12697-18 are the method with a basket and Schellenberg’s method. The method with a basket after EN 12697-18 (Part 1) is mainly used for draindown testing of porous asphalt. In principle, it is possible to determine only binder draindown but not mastic

Draindown Test Parameters according to AASHTO T 305-97

![]() Four total; test two samples of a mix at each of the two test temperatures.

Four total; test two samples of a mix at each of the two test temperatures.

Samples are to be tested at two temperatures:

1. The expected production temperature in an asphalt plant (two samples)

2. A temperature higher by 15°C than the expected production temperature (two samples)

1200 ± 200 g

60 ± 5 minutes (or 70 ± 5 minutes in case of oven cooling)

1. Weigh the tray to catch flowing mastic to an accuracy of 0.1 g.

2. Mix components of an SMA mix at a fixed temperature.

3. Put the prepared mix into a weighed wire basket; do not pack the mix into the basket, and do not postcompact it either.

4. Measure the basket mass with an accuracy of 0.1 g.

5. Check the temperature of the mix; it should not drop by more than 25°C below the desired test temperature. If it does cool too much, the mix should be kept in the oven for 10 minutes longer, (i. e., up to 70 minutes).

6. Place the basket with the mix on the tray, and then put it into the oven for 60 ± 5 minutes.

7. Remove the tray with the basket from the oven, and weigh the basket with the mix or the tray itself with an accuracy of 0.1 g.

8. Determine draindown as a percentage of the mastic mass remaining on the tray in relation to the total mass of the mix before testing.

• When stirring the mix components, pay attention to the proper sequence of their dosages, particularly fibers, polymers, and so on.

• The temperature of aggregate in the oven (before mixing) cannot exceed the desired production temperature of a mix by more than 28°C.

• The final result is the arithmetic average of the two samples at each test temperature.

|

FIGURE 8.3 The wire basket for draindown testing according to AASHTO T 305-97. (Photo courtesy of Karol Kowalski and Adam Rudy, Purdue University.) |

because the basket used here has small perforated holes. Moreover, these holes may be blocked during the testing of mixes containing larger quantities of mastic and fiber stabilizers. This is the reason why that method has limited application for SMA draindown testing.

Schellenberg’s method according to EN 12697-18 (Part 2) has been applied in draindown testing of porous asphalt containing fibers and other asphalt mixes like SMA. The essential information on that method is shown in Table 8.3.

Leave a reply