Final Remarks

The layer edge should be rolled with a machine fitted with a side-roll; this will enable suitable compaction of the area close to the edge. The drums of a roller should be moistened with water, which should protect them against mastic adhesion and dragging particles out.

10.5 pLAcEMENT of sMA IN KOMPAKTASPHALT TEcHNIQuE

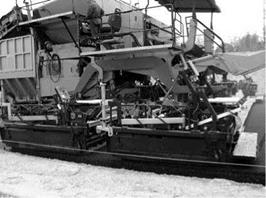

The Kompaktasphalt method consists of placing two layers of a pavement in one pass of a specially designed paver (Figure 10.12). Typically the paver places both an SMA and asphalt concrete in one pass. The first attempt at such a laydown occurred

|

FIGURE 10.12 Special paver for the placement of two layers in one pass with an SMA wearing course (A2 highway in Poland), an example of Kompaktaspha. lt technology. (Photo courtesy of Konrad Jablohski.) |

in 1995 Germany and was made by Elk Richter of Fachhochschule Erfurt and the company Hermann Kirchner GmbH&Co KG on Highway A4 (Richter, 1997). In December 1998, also in Germany, a special modular paver was used for the first time (Utterodt and Egervari, 2009). This technology has been chiefly applied in Germany. Undoubtedly, the simultaneous placement of two layers has a number of strong points. It is enough to mention just the following:

• Excellent interlayer bonding (i. e., the “hot-on-hot” placement)

• Great thermal capacity of the two layers together (thickness of 10-12 cm), giving more time for compacting, especially on cool days

• Rapid progress in work (two layers at the same time)

The use of the Kompaktasphalt technology carries with it some additional requirements for the construction site organization:

• The mixture intended for a particular site comes from two, sometimes even three, asphalt plants with sufficient capacity to supply the paver.

• An adequate number of transport vehicles are essential to haul mixtures from asphalt plants to the construction site.

This frequently adopted scheme provides for the placement of an asphalt concrete intermediate layer and an SMA wearing course. Various thicknesses and gradation of SMA layers are used, with 4-cm of SMA 0/11 mm and 3-cm of SMA 0/8 mm being used most often.

Leave a reply