REPOINTING MORTAR JOINTS

Even materials as durable as brick and mortar break down in time, most commonly near the top of a wall or chimney, where masonry is most exposed to the elements. Often, the structure wasn’t capped or flashed properly. If the bricks are loose, remove them till you reach bricks that are solidly attached. If joints are weathered but bricks remain firmly attached, repoint (or tuck-point) the joints by partially cutting back the mortar, adding new mortar, and shaping the joints. If the brick is painted, see "Stripping Painted Brick,” on p. 191.

Finally, if vertical or diagonal cracks run through several courses, there may be underlying structural problems, which must be corrected before repointing. In this case, consult a structural engineer.

Raking old mortar...

read more

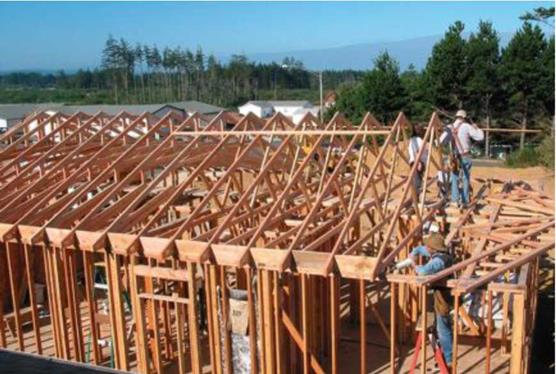

Rolling roof trusses. The first truss you should nail in place is the one for the gable end. Then it’s just a matter of rolling the remaining trusses in place, setting them on their layout marks, and nailing them down. You can do this while standing on the walls or by working off a ladder...

Rolling roof trusses. The first truss you should nail in place is the one for the gable end. Then it’s just a matter of rolling the remaining trusses in place, setting them on their layout marks, and nailing them down. You can do this while standing on the walls or by working off a ladder... ■ BY MATTHEW TEAGUE

■ BY MATTHEW TEAGUE

TWO WAYS TO CUT BRICK

TWO WAYS TO CUT BRICK