TURNING CORNERS IS TRICKY WORK

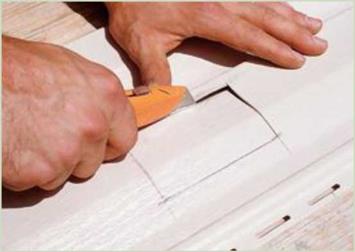

Combining an enclosed soffit with a gable-end roof overhang means that you need to construct a boxed return. The return creates the nailing surfaces required to bring the soffit and fascia trim around the corner of the house. Here’s how to do the job:

1. Use 2x lumber to make the framing for the boxed return, which consists of a triangular piece cut to match the roof’s pitch and a straight board that vertically extends to the gable wall.

2. Fasten this assembly to the bottom edge of the barge rafter and the back wall. The soffit paneling must be attached prior to the aluminum cladding.