TURNING CORNERS IS TRICKY WORK

Combining an enclosed soffit with a gable-end roof overhang means that you need to construct a boxed return. The return creates the nailing surfaces required to bring the soffit and fascia trim around the corner of the house. Here’s how to do the job:

1. Use 2x lumber to make the framing for the boxed return, which consists of a triangular piece cut to match the roof’s pitch and a straight board that vertically extends to the gable wall.

2. Fasten this assembly to the bottom edge of the barge rafter and the back wall. The soffit paneling must be attached prior to the aluminum cladding.

4. To install gable-end siding panels, nail white J-channel trim along the rake. Trim the panel ends to match the roof’s pitch.

We have to set up scaffolding to finish the siding and soffit work; by this time, the house is really looking great.

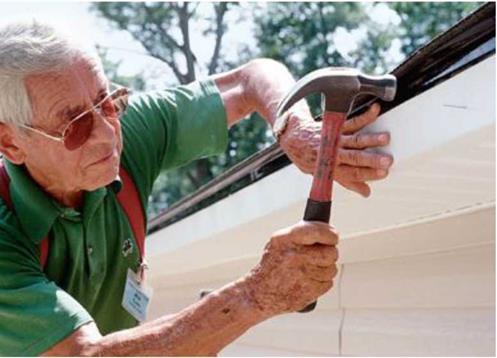

After a break to admire our progress (and clean up the spare pieces of vinyl siding), we start to cut and bend the aluminum cladding that will cover the fascia boards and the barge rafters.

A big bending tool, called a brake, creases the aluminum perfectly straight.

When it slides into place over the wood, it looks like it belongs there.

When it slides into place over the wood, it looks like it belongs there.

|

|

||

|

The cladding that covers the boxed return is a bit more complex, but the bends can be made with a hand brake. At the ridge peak, run one piece of aluminum past the centerline, then cut the second piece plumb to give the trim a finished appearance.

Any time you use aluminum to cover gutter boards, posts, or beams, make absolutely sure that no water can get behind the aluminum. You can do this by overlapping adjacent sections of cladding by 3 in. to 4 in. and by ensuring that a higher section of cladding (on a barge rafter, for example) always overlaps a lower section.

Leave a reply