Copper Pipe: Disconnecting, Reconnecting, and Repairing

To disconnect a soldered fitting, apply heat till the solder melts. Then gently tap the fitting off the pipe. When the metal is cool, clean the pipe end, reflux, reheat, and solder on a new fitting. Unless the fitting is an expensive one, such as a gate valve, don’t reuse fittings that have already been soldered.

When disconnecting a fitting on an existing supply line, drain the pipe first; otherwise, the solder won’t melt. Draining and reconnecting will be much easier if the pipe section can be isolated with a shutoff valve, but sometimes old valves don’t shut perfectly. In that event, ball up a piece of white bread and stick it in the pipe to block the trickle while you solder. Once the water runs again, the bread will dissolve and flush out.

Finally, here’s a fix for split pipes that do...

read more

Typical parking areas in Lacey are built on a 6-inch subbase and a 2- inch crushed stone base. After conducting soil-bearing tests, the developer of The Park requested and received approval to construct parking areas with a 2-inch crushed stone base and a 2-inch asphalt cover.

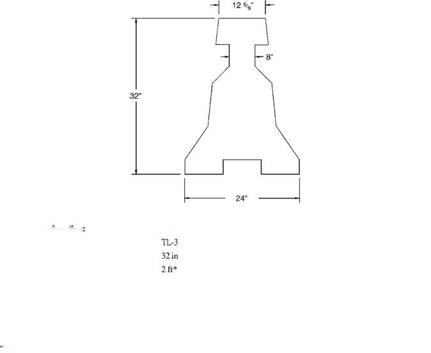

Typical parking areas in Lacey are built on a 6-inch subbase and a 2- inch crushed stone base. After conducting soil-bearing tests, the developer of The Park requested and received approval to construct parking areas with a 2-inch crushed stone base and a 2-inch asphalt cover. AASHTO Designation

AASHTO Designation