Edge Sealing

In regard to edge sealing, the following reasonable solution definitely extends the durability of a pavement and has been adopted in German practice (Milster et al., 2004):

• An extra layer of tack coat (of hot binder) is placed on the edges of pavement (between the layers), minimum 10 cm wide.

• A binder layer, minimum 2 mm thick, on a side surface of all layers, is applied (to achieve such a layer of binder, the tack coating usually needs to be repeated, or a hot sealant 2 mm thick needs to be applied in one working cycle).

This sealing is aimed at protecting the pavement against water infiltration between layers and inside them.

Before opening up a road section with a new SMA layer to traffic, one should be sure that it has sufficiently cooled...

read more

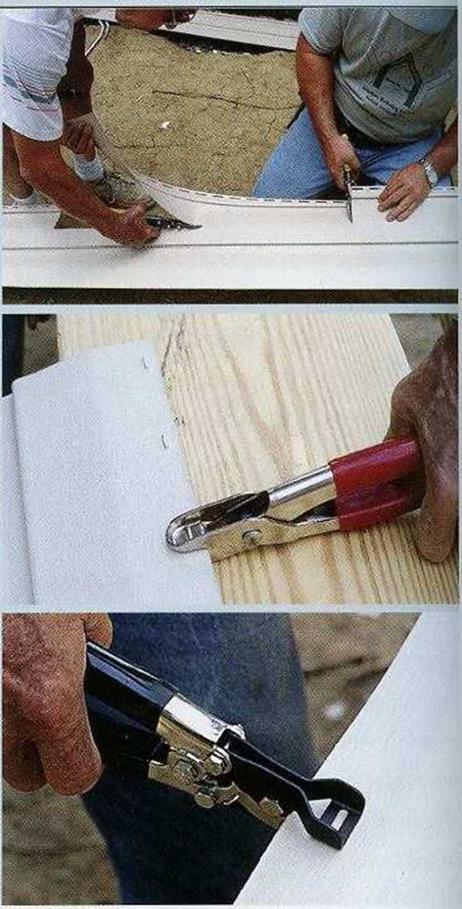

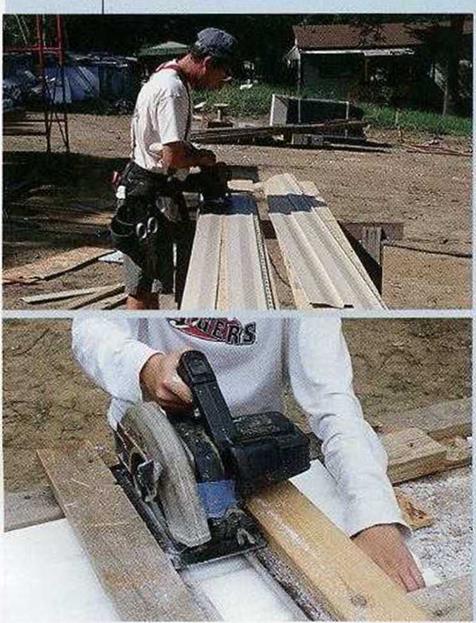

A LONG, FLAT work surface is essential for vinyl siding and sheet-metal work. A couple of 2×12 boards on sawhorses work fine. For precise 90-degree-angle cuts and angled rake cuts, I suggest making a cutting jig for a circular saw (see the photo at bottom left). The jig, which sits on a long worktable, is essentially a wooden cradle that guides the base of the circular saw. The cradle can be positioned at a right angle, or at

A LONG, FLAT work surface is essential for vinyl siding and sheet-metal work. A couple of 2×12 boards on sawhorses work fine. For precise 90-degree-angle cuts and angled rake cuts, I suggest making a cutting jig for a circular saw (see the photo at bottom left). The jig, which sits on a long worktable, is essentially a wooden cradle that guides the base of the circular saw. The cradle can be positioned at a right angle, or at other angles, to the siding.

other angles, to the siding.