CHOOSING CAULKS AND SEALANTS

If you walk down the caulk and sealant aisle at any well-stocked hardware store or home center, it’s easy to feel overwhelmed by the variety of products available. For quite a few years now, the terms “caulk" and “sealant" have been used interchangeably. In technical terms, sealants are supposed to be more flexible than caulks, meaning that they are able to expand and contract with the movement of materials. But even caulk and sealant manufacturers have different definitions for these materials. For this reason, it’s smart to ask local builders and knowledgeable building-material suppliers which caulks and sealants are recommended for various jobs.

Although manufacturers haven’t cleared up the distinction between caulks and sealants, they have improved their labeling with regard to specific applications. For example, “painter’s caulk" is an inexpensive latex-type caulk that is primarily used to fill gaps in and around interior trim prior to painting. Caulk that is labeled “for kitchen and bathroom use" is waterproof and will adhere to tile, porcelain sinks, acrylic shower units, and other surfaces found in those rooms. Silicone and urethane sealants are usually more expensive than acrylic or latex-acrylic caulks and are primarily used in exterior applications where extra durability, flexibility, and weather resistance are important. But be aware that acrylic paint does not adhere to some silicone caulks. Check with your supplier to see if your paint and caulk are compatible.

Caulks and sealants can be useful on small openings

For filling small gaps (up to lA in. or so), caulks and sealants sometimes work as well as, or better than, foam. A good sealant has sufficient flexibility to maintain a seal even though the joint expands and contracts slightly. For advice on selecting caulks and sealants, see the sidebar on p. 199.

If you plan to use caulk or sealant to fill a gap wider than /4 in., it’s a good idea to insert a backer rod into the joint before you apply the sealant. Available where caulks and sealants are sold, backer rod is made from dense, compressible foam. When wedged into a joint, it helps seal the area and lets you apply a thinner bead of caulk or sealant.

Although there is no standard approach to building a tight, comfortable, and energy-efficient house with good indoor-air quality, it’s not difficult to achieve those goals if you understand how a house works in terms of insulation, airtightness, and ventilation. This is especially true with the basic, affordable houses that Habitat builds. This chapter explains the concepts, materials,

Although there is no standard approach to building a tight, comfortable, and energy-efficient house with good indoor-air quality, it’s not difficult to achieve those goals if you understand how a house works in terms of insulation, airtightness, and ventilation. This is especially true with the basic, affordable houses that Habitat builds. This chapter explains the concepts, materials,

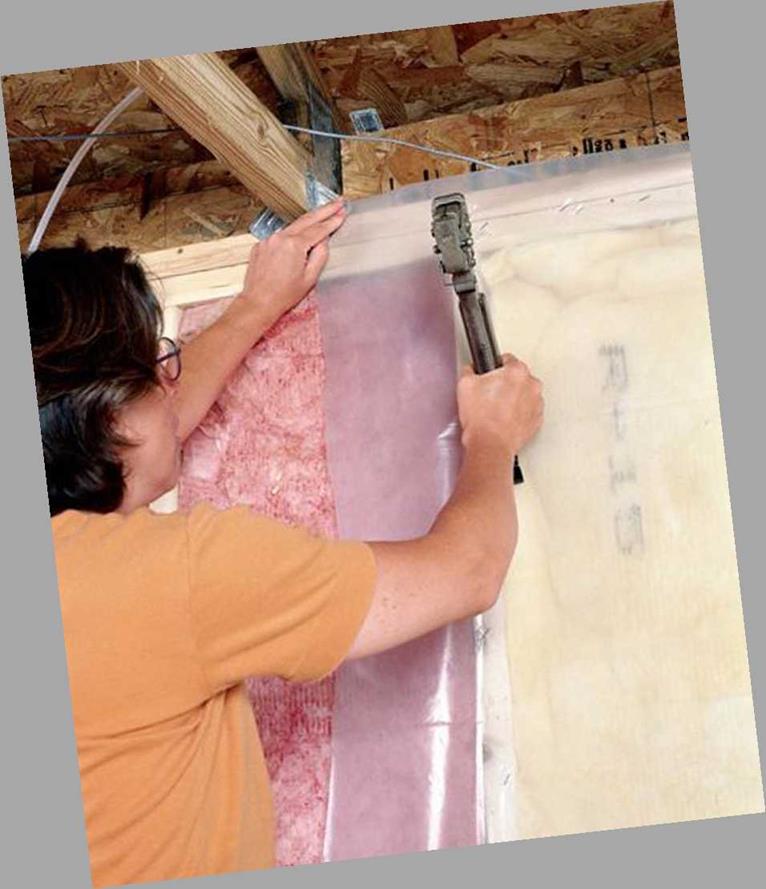

[Photo © Larry Haun]

[Photo © Larry Haun]

another near the edge of the porch maintains consistent spacing. Where a board crosses a joist or beam, drive two decking screws. Those steel screws have a galvanized or polymer coating that protects against rust, and their coarse threads drive quickly and hold much better than nails do. To install l’T-in.-thick decking, use 3-in. screws. To install 5/4 boards, 21/2-in. screws will do. Although it takes a bit more time, I predrill the screw holes in the decking with a 3/i6-in.-dia. bit. This makes it easier to pull the boards tightly against the framing and just about eliminates the possibility of splitting a board.

another near the edge of the porch maintains consistent spacing. Where a board crosses a joist or beam, drive two decking screws. Those steel screws have a galvanized or polymer coating that protects against rust, and their coarse threads drive quickly and hold much better than nails do. To install l’T-in.-thick decking, use 3-in. screws. To install 5/4 boards, 21/2-in. screws will do. Although it takes a bit more time, I predrill the screw holes in the decking with a 3/i6-in.-dia. bit. This makes it easier to pull the boards tightly against the framing and just about eliminates the possibility of splitting a board.

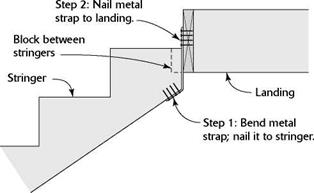

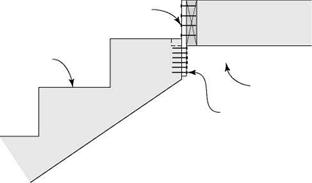

2×6 rim joist. Then measure down 71/2 in. from the top of the rim joist, mark the board on each end, and strike a line across it at that height. Drive 8d galvanized nails through the back of the hanger board and into the stringers below the 2x 6 rim, making sure the top of the upper cleats on both outboard stringers and the top notch on the interior stringers land on the line you snapped on the hanger board. To stiffen the top of the stairs, cut and install PT 2×4 blocking between the stringers.

2×6 rim joist. Then measure down 71/2 in. from the top of the rim joist, mark the board on each end, and strike a line across it at that height. Drive 8d galvanized nails through the back of the hanger board and into the stringers below the 2x 6 rim, making sure the top of the upper cleats on both outboard stringers and the top notch on the interior stringers land on the line you snapped on the hanger board. To stiffen the top of the stairs, cut and install PT 2×4 blocking between the stringers.