Other Techniques for Discharging Mixture

Special self-propelled hoppers (e. g., MTVs) have been used to avoid segregation during the discharge of a mixture from the dump truck to the paver hopper and to minimize the risk of placing cool mixture (by remixing). These mobile machines operate between the dump truck and the paver to eliminate any contact between the two. MTVs are equipped with conveyors to transport the mixture to the paver hopper. These devices eliminate jarring of the paver caused by contact with the delivery trucks or by the mass of mix dropping into the hopper. They hold a larger mass of material than a paver hopper, which helps to keep the temperature high, and allows the paver to keep moving forward. Another advantage of MTVs is the possibility of remixing the mixture constituents. This eliminates the risk of segregation and

|

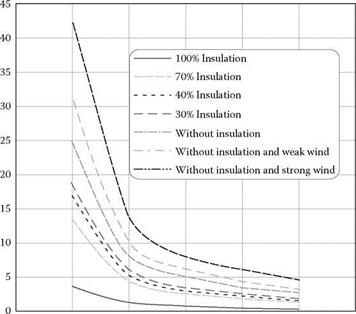

0 5 10 15 20 25 30 Haul truck loading, Mg FIGURE 10.3 Impact of load capacity and applied insulation of the truck bed on the temperature drop of mixture in various weather conditions. (From Spuziak, W., Proceedings of the 6th International Conference Durable and Safe Road Pavements, Kielce, Poland, 2000. With permission.) |

enables the breaking of large lumps of cool mixture that may occur during transportation. Then the mixture is transferred to the paver hopper using a conveyor belt. MTVs are especially useful when laying mixtures susceptible to segregation and paving during cooler periods of the year (see Chapter 11, Section 11.8).

Leave a reply