Construction Considerations for Soil Nailed Walls

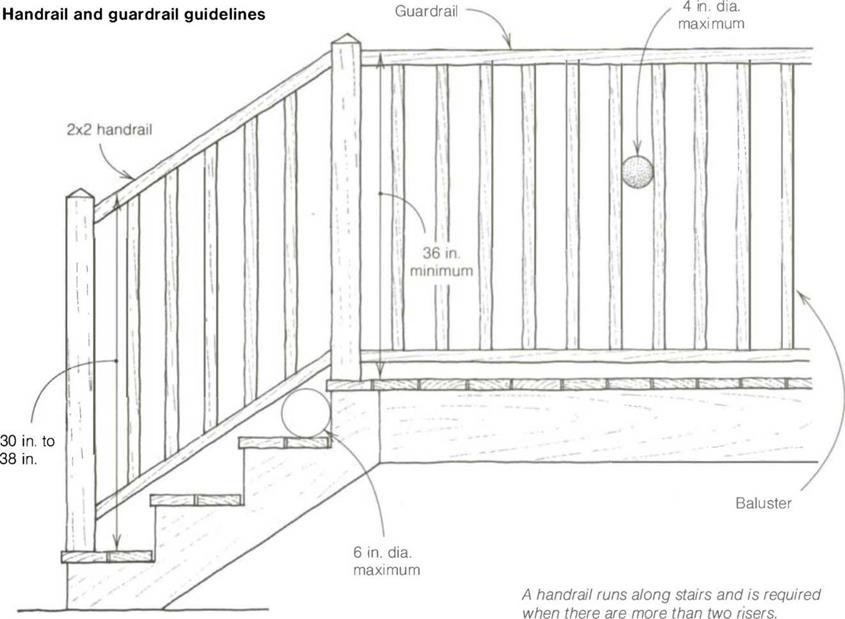

The construction sequence is typically to excavate, nail, and shotcrete the face in increments from the top down. Figure 8.56 shows a schematic of a sequence for underpass widening. Where face stability is a concern, a flashcoat of shotcrete may be applied before nail installation. The most common method of nail installation in

FIGURE 8.56 Construction sequence for soil nailed wall used in widening of underpass. (From Oregon Department of Transportation, with permission)

|

all nail layers |

STEP 7: Place second structural application to full height and architectural finish

FIGURE 8.56 (Continued)

Europe, as in the United States, is the drill-and-grout method. Most commonly, the steel tendon is installed prior to grouting, although this sequence is sometimes reversed...

read more