Determination of optimal maintenance schedule

In Sec. 6.3.4 it was shown that the implementation of scheduled maintenance can increase the mean time to failure (MTTF) of a system having an increasing hazard function. Increasing maintenance frequency would result in a decrease in repair frequency and vice versa. Suppose that an engineer is considering implementing a regular scheduled maintenance for a system. The problem of interest is to determine the optimal maintenance frequency associated with the minimum total cost, which includes the maintenance cost and repair cost. Of course, the issue is worth considering if the cost of maintenance is much

lower than the cost of repair. Otherwise, there will be little economic incentive to conduct scheduled maintenance. The following descriptions show a simple example of determining the optimal maintenance schedule associated with the minimum total cost of repair and maintenance. More sophisticated models for dam safety inspection have been developed by Tang and Yen (1991, 1993).

The total cost per unit time with a maintenance cycle of time interval length tM can be expressed as

TC(tM) = Cr x fu(tM) + Cm x fM(tM) (8.25)

in which CR and CM are unit cost per repair and unit cost per maintenance, respectively, and f R and fM are the repair and maintenance frequencies, respectively.

Assume that the repair is ideal. The repair frequency (number of repairs per unit time) f R for a specified maintenance interval tM can be calculated by

1 tM

fu (tM) = ft (r )dr (8.26)

tM 0

|

|

in which ft (t) is the failure density function. On the other hand, since there will be one maintenance within each scheduled time interval tM, the maintenance frequency is 1/tM. Therefore, the total cost per unit time is

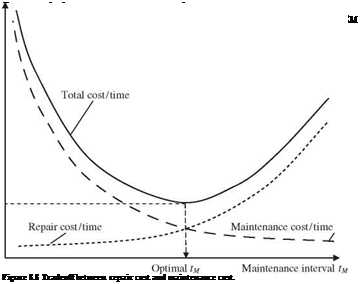

The relationships between the three cost items and the scheduled maintenance interval are shown in Fig. 8.8, which shows that the repair cost per unit time increases with tM, whereas the maintenance cost per unit time decreases with tM. Therefore, there is a tradeoff between the two cost components, and the objective is to determine the optimal scheduled maintenance interval tM associated with the least total cost.

The optimal scheduled maintenance time interval can be obtained by solving d[TC(tM)]/d (tM) = 0, that is,

In general, solving Eq. (8.28) requires the use of numerical root-finding procedures.

Leave a reply