PREPARING FOR SANDING

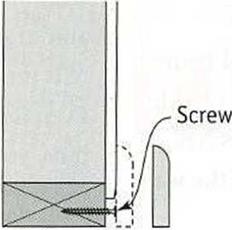

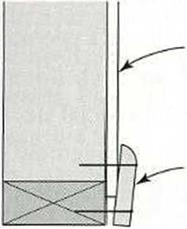

After testing floors to determine their finish, empty rooms of all movable items (don’t forget window blinds and shades). Then use 3-mil polyethylene sheeting to cover the cabinets, radiators, smoke detectors, doorways, and heating or airconditioning openings, using painter’s tape to avoid pulling paint off the walls and trim. Dust migrates through the smallest openings, so use painter’s tape to seal the perimeters of closed doors and keyholes. Because baseboards will get bumped by edgers, remove them if possible— though often that’s not possible. Alternatively, you can use a metal shield to protect such trim, as shown in the top photo on p. 493.

Vacuum the floor so you can survey it closely for nails sticking up, and floorboards that are split or uneven...

Vacuum the floor so you can survey it closely for nails sticking up, and floorboards that are split or uneven...

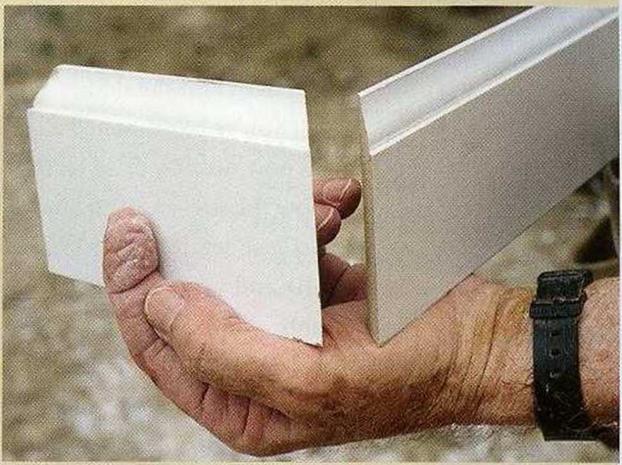

THE JOINTS IN BASEBOARD SHOULD BE CLOSE TO PERFECT. Minor touchups with latex caulk can be done before painting. Unfortunately, it’s not so easy to make perfect joints at corners when the drywall is not straight or a corner is not square.

THE JOINTS IN BASEBOARD SHOULD BE CLOSE TO PERFECT. Minor touchups with latex caulk can be done before painting. Unfortunately, it’s not so easy to make perfect joints at corners when the drywall is not straight or a corner is not square.