Techniques FITTING BASEBOARD IN IMPERFECT CORNERS

THE JOINTS IN BASEBOARD SHOULD BE CLOSE TO PERFECT. Minor touchups with latex caulk can be done before painting. Unfortunately, it’s not so easy to make perfect joints at corners when the drywall is not straight or a corner is not square.

THE JOINTS IN BASEBOARD SHOULD BE CLOSE TO PERFECT. Minor touchups with latex caulk can be done before painting. Unfortunately, it’s not so easy to make perfect joints at corners when the drywall is not straight or a corner is not square.

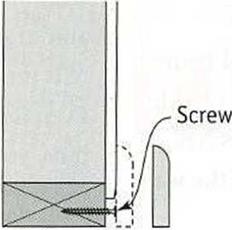

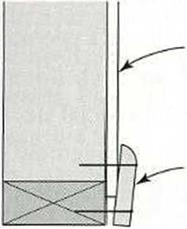

On inside corners, drywall can be tipped back, causing a coped or mitered baseboard joint to open.

This can be remedied by putting a shim behind the tipped trim so that it sets straight up and down.

Instead of a shim, I sometimes drive a drywall screw into the bottom plate to hold the baseboard square (see the illustration below).

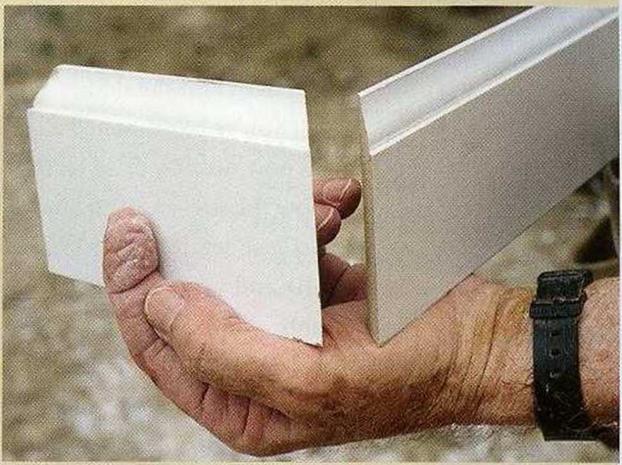

I use two short pieces of baseboard with mitered

PREVENTING BASEBOARD FROM TOEING IN

|

|

|

Drywall |

|

Baseboard |

(45-degree) ends to check outside corners for square (see the photo above). If the mitered joints fit perfectly, the corner is square. If not, note whether the joint is open at the heel (the back corner of the baseboard) or at the toe (the front edge). If it’s open at the heel, set the chopsaw at a 44-degree angle (or less, if necessary) before making the cut.

If it’s open at the toe, set the saw at a 46-degree angle (or more, if appropriate). Rather than waste long pieces of material, make practice cuts on scrap until you get the right fit.

FINISH UP. Pieces of baseboard will be at slightly different elevations where carpeting meets vinyl flooring. Join the two pieces of baseboard with a square cut, and use sandpaper to round the corner of the higher piece so that it meets the lower one (see the illustration on the facing page).

Other situations require a bit of finesse.

For example, you can’t run baseboard in front of a heat register that goes all the way to the floor. In that situation, bevel each end cut 15 degrees instead of making a right-angled cut (see the illustration on the facing page).

Cabinet manufacturers sometimes supply a prefinished baseboard that matches their cabi

nets. This base material is cut and nailed under the front of the cabinets in the toekick space. Once installed, it hides the joints between the cabinets.

If that cabinet trim is not available, you can cover the toekick area with a regular piece of baseboard trim. You may also want to install base shoe, or shoe trim, a small, quarter- round type of molding that is often used with baseboard trim (see the illustration on the facing page). Shoe trim hides any space that may exist between the baseboard and hardwood or vinyl flooring. Because it’s so small, it’s quite flexible (much more so than baseboard), so it can be bent to fit the contour of a wavy wall

or floor. It is not needed with carpeting because carpeting fills the space between the baseboard and the floor.

or floor. It is not needed with carpeting because carpeting fills the space between the baseboard and the floor.

If you’ve hand-nailed all the interior trim, you now need to drive all the finish nails below the surface of the wood with a nail set. Once set, the holes can be filled with putty and sanded in preparation for painting. Caulk along the top edge of the baseboard trim and along the casings to fill any gap between the trim and the wall. Remember that caulk shrinks, so some gaps may need a second application. Take your time when caulking baseboard. Leave joints looking neat, not messy.

Leave a reply