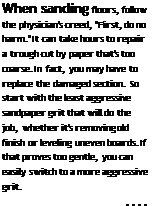

Floor-Sanding Materials*

![]()

put a lamb’s wool buffing pad on the buffer to bring up the sheen of a finish; thus it’s often used to buff out a new wax coat.

Hand scrapers and sanding blocks reach corners, flooring under cabinet toekicks, and other places edgers can’t reach. Hand scraping is tedious, but it goes more quickly if you periodically use a fine metal file known as a mill file (bastard file) to sharpen the scraper blade.

Other hand tools you’ll need include a nail set to sink nail heads below the surface of the wood before you begin sanding, a hammer, and wide – blade spackling knives or metal squeegees to apply wood filler. If you cut your own edger disks, you’ll need a pair of heavy scissors.

Brushes and applicators should be matched to specific finish types. You’ll find those tools discussed and paired with finishes in "Finishes, Cleaning Solvents, and Applicators,” on p. 494.

Personal safety equipment is not optional. Get a close-fitting respirator mask with organic vapor filters. During the sanding phases, wear eye goggles with side vents; vented goggles admit a bit of sanding dust, but they won’t cloud up with water vapor. Drum sanders and edgers are noisy and tiresome; wearing hearing protection will keep you alert longer, so you’ll be less likely to gouge the floor because you’re punchy with fatigue. Wear disposable plastic gloves when applying finishes or wood filler. If you can, buy latex-free nitrile plastic gloves, which auto mechanics, gardeners, and postal workers swear by. Nitrile gloves are tough enough to withstand automotive

solvents and garden grit, yet thin enough to sort mail with. You can easily find nitrile gloves at auto parts stores, typically sold in boxes of 50 to 100 in sizes ranging from small to extra large.

Edging and hand scraping are hard on your knees, so get a pair of kneepads comfortable enough to wear all day.

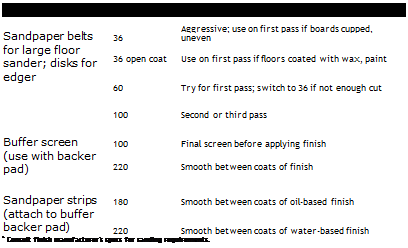

Rent a heavy-duty vacuum, since there’s no point in frying a home vac that’s really not up to the task. Ideally, the vacuum should have a HEPA (high-efficiency particulate air) filter to capture dust rather than recirculate it into the room, but not all rental companies carry them. A backpack vac, shown in the bottom photo on the facing page, is less likely to bash woodwork and has no wheels to compact sawdust, but most rental companies offer only wheeled canister types.

Sandpaper and buffer screens are rated according the concentration of grit per square inch. The lower the grit number, the larger, coarser, and more widely spaced the grit particles. Lower-grit papers cut more aggressively. Whereas, the higher the grit number, the finer and more closely spaced the grit. Consequently, as you sand floors, each grit should be slightly finer than the preceding one, smoothing out scratches of the previous grits, till you arrive at the grit level specified on the label of your floor finish. Always read the finish manufacturer’s sanding requirements before renting equipment and buying sanding material.

If you’re sanding floors to bare wood, you’ll typically need to make two or three passes with a large floor sander and an edger and one pass with a buffer with abrasive screen, before floors are smooth enough to apply finish. (Vacuum after each pass.) Get 36-grit, 60-grit, and 100-grit paper for the floor sander and the edger; both use the same grit on each pass. To screen the floor before finishing, buff with 100-grit screens backed by a nylon backing pad. To smooth between coats, use a 220-grit screen, or hook – and-loop sandpaper strips that attach to the buffer pad.

Note: If floors are coated with paint or wax— which gum up sandpaper quickly—use open-coat sandpaper for the first sanding pass. You can use regular closed-coat sandpaper (most sandpaper is closed coat) for subsequent passes.

If you’re simply recoating a finished floor, you probably won’t need a drum sander and an edger; a buffer with a nylon pad and two grades of screen (100 grit and 220 grit) should do the job. Again, check your floor finish’s label to see what grit sandpaper to use between coats. Finally, sandpaper wears out quickly, so get more than

you think you’ll need. Most rental companies will credit you for unused paper when you return the equipment.

Leave a reply