FRAMING A PLATFORM FOR A FORCED-AIR HEATING UNIT

![]()

|

|

|

|

||

FRONT VIEW

36 in.

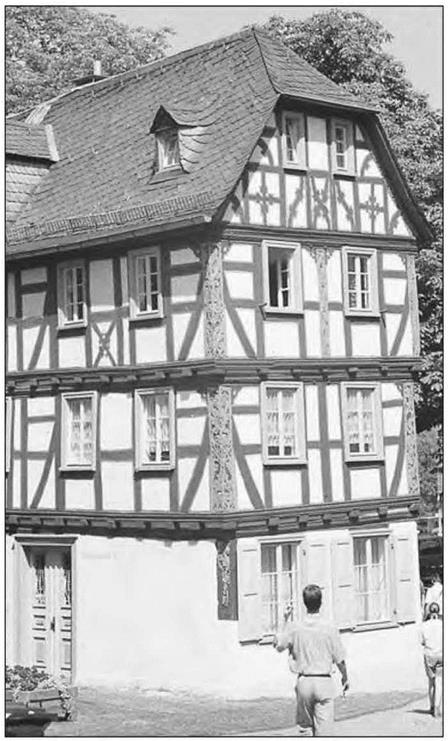

Some furnace rooms need a platform so the heating unit can receive combustion air from below.

my carpenter-daughter, you can hop right up on the plates and start lying the walls together. Otherwise, it’s best to work on a sturdy ladder.

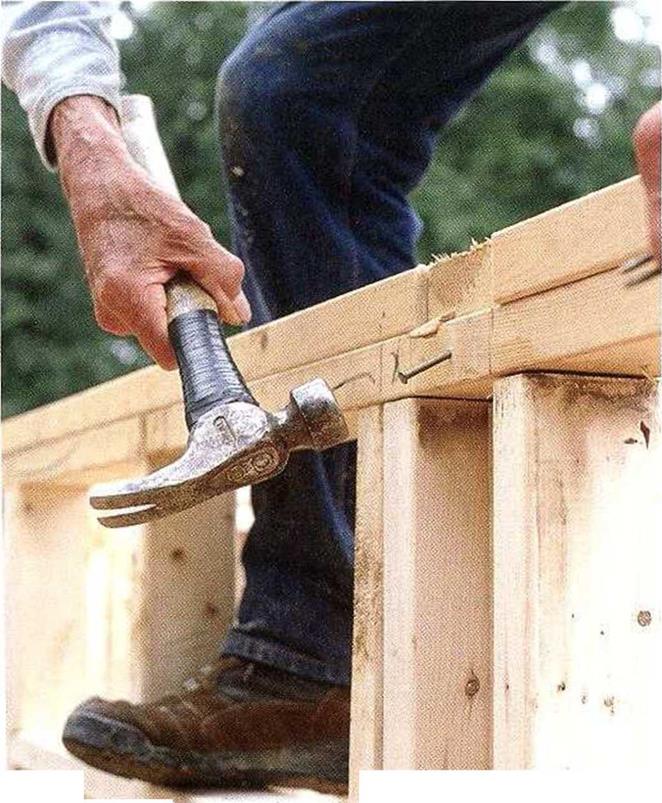

The corner marks you drew on the plates earlier now serve as guides when railing off the top plates. Make sure that the double top plate is on these lines and that the top plates of both walls are touching. If necessary, toenail a 16d nail up through the top plate of the through wall into the double top plate of the butt wall to draw everything together, as shown in the photo at left. Nail two I6d nails through the lap into the intersecting wall.

TOENAIL THE TOP PLATE...

read more