Steel-Beam Bridge

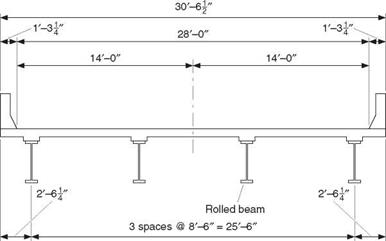

The steel-beam bridge uses rolled steel beams as shown in Fig. 4.8. Beam depths of 44, 40, and 36 in (1118, 1016, and 914 mm) are available, as well as shallower sections. Check with producers on current availability of the deeper sections from domestic sources because federal law applicable to federally aided projects, as well as many state laws, prohibits the use of foreign steel.

Steel beams may be made continuous by welding or bolting sections in the field. In the past, some states made welded connections at the piers, and currently at least

|

FIGURE 4.8 Cross-section of bridge with rolled steel beams. Conversions: 1 in = 25.4 mm, 1 ft = 0.305 m. |

one state makes welded connections at contraflexure points, supporting the field sections temporarily and providing enclosures to shield...

read more

Make sure you spend some time cleaning up the job site at this point in your project...

Make sure you spend some time cleaning up the job site at this point in your project...