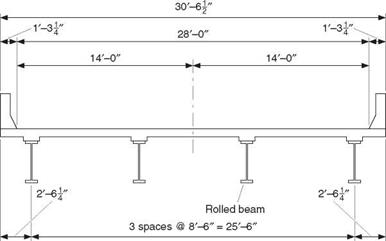

Steel-Beam Bridge

The steel-beam bridge uses rolled steel beams as shown in Fig. 4.8. Beam depths of 44, 40, and 36 in (1118, 1016, and 914 mm) are available, as well as shallower sections. Check with producers on current availability of the deeper sections from domestic sources because federal law applicable to federally aided projects, as well as many state laws, prohibits the use of foreign steel.

Steel beams may be made continuous by welding or bolting sections in the field. In the past, some states made welded connections at the piers, and currently at least

|

FIGURE 4.8 Cross-section of bridge with rolled steel beams. Conversions: 1 in = 25.4 mm, 1 ft = 0.305 m. |

one state makes welded connections at contraflexure points, supporting the field sections temporarily and providing enclosures to shield the joint from wind. More commonly, field sections are spliced by high-strength bolts, using web-and-flange splice plates. Bolts may be installed using calibrated wrenches, by the turn-of-nut method, or by use of tension-indicating washers, depending on what the designer allows and what the erector prefers to use. With all methods of bolting, it is important to use a procedure and sequence of bolting that will compact the joint and prevent a bolt initially adequately tightened from losing tension when subsequent bolts in the joint are tightened. Fasteners are generally ASTM A325 or A490 high-strength bolts.

To increase the span capacity of a rolled beam, or to permit a lighter beam to be used, cover plates may be added above the top flange and below the bottom flange in regions of high bending stress due to both positive and negative moments. The fatigue strength at the end of the cover plates, which is generally at a point of low maximum stress but high stress range, is much less than the fatigue strength of the unplated beam. Allowable fatigue stresses must not be exceeded, and this consideration may favor an unplated beam. However, an improved detail is available that uses bolts at the end of the plate, and the fatigue strength is somewhat higher. New Jersey DOT requires full-length cover plates, with termination about 2 ft (610 mm) from the end of the beam where the stress range is very small.

Leave a reply