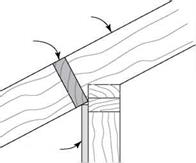

INSTALLING FRIEZE BLOCKS BETWEEN. RAFTERS AND TRUSSES

![]()

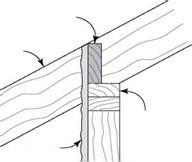

2x frieze block

Rafter

Double top plate

Stucco

When installed plumb, a frieze block provides backing for stucco.

2x frieze block

Siding

Trusses by themselves are rather fragile. They gain strength when they’re properly blocked and braced. I will now explain various blocking and bracing strategies, because this work needs to be done as the trusses are installed.

Hurricane clips and frieze blocks

A hurricane can tear a roof completely off a house. Hurricane clips, which are designed to prevent this, are required by code in some parts of the country. After the trusses are nailed in position, hurricane clips are easy to install from inside or outside the house. Drive nails into the trusses and the top plates of the wall (see the bottom left photo)...

read more