Obstacles

Roadside obstacles include nontraversable terrain and fixed objects, either constructed (such as culvert headwalls or structural supports) or natural (such as trees). Such obstacles account for over 30 percent of highway fatalities. The need for a barrier depends on both the nature of the obstacle and the probability that it will be hit. Table 6.1 lists the major types of obstacles and considerations for barrier warrants. Refer to the clear zone chart (Fig. 6.2) as a guide in determining whether the location of an obstacle constitutes a significant threat.

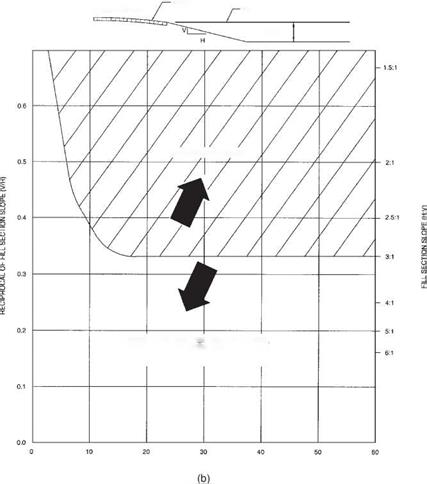

FIGURE 6.12 (Continued)

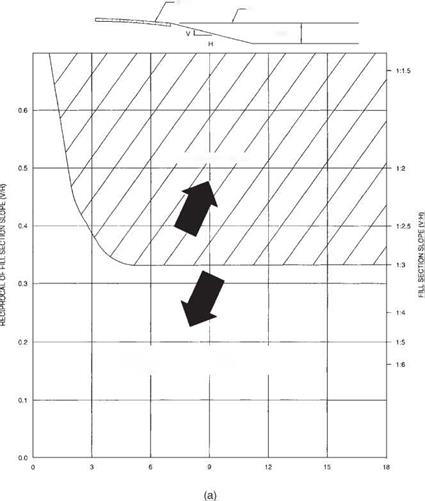

FIGURE 6.12 (Continued)

FILL SECTION HEIGHT (m)

FILL SECTION HEIGHT (m)