Making Sense of Flexible Metal Cable

There are two main types of flexible metal cable, armor clad and metal clad. Outside, they look about the same. (For a comparison, see the photo on p. 238.) The main difference is that MC cable contains an insulated ground wire so it can ground equipment and tools with a three-prong plug. MC cable assemblies should be used in exposed dry locations, such as garages and basements. PVC-jacketed MC cable can be used outdoors, but it is so expensive that it is rarely used in residences. Note:

Exposed doesn’t mean "exposed to the elements." Here it means visible and accessible— not hidden behind finish walls.

AC cable, on the other hand, contains no ground wire; rather, its metal sheathing serves as an equipment ground. AC should be used only in dry, indoor locations. The thin, uninsulated copper aluminum wire inside AC is not a conductor; it’s a bonding wire, which enhances the grounding ability of the armor itself. That is, AC’s grounding path is its metal sheathing.

The NEC allows both MC and AC to be used in branch circuits, but for the reasons just cited, many local codes allow only MC in new construction. In the text, MC is the default term for any flexible metal cable.

|

|

sometimes used as a whip, a short section of exposed cable that connects permanent appliances or lighting fixtures to a circuit.

There are at least two ways to cut MC cable. The first method requires looping and squeezing the cable till its coils pucker and then snipping through the pucker with metal shears or diagonal-nose cutters, being careful not to nick the insulated wires inside. The second method is often required by local codes and is far easier: The rotary cable cutter shown in the photo below uses a hand-cranked cutting wheel to cut through metal sheathing. Once the tool cuts through a coil, slide the severed sheathing off the insulated wires inside.

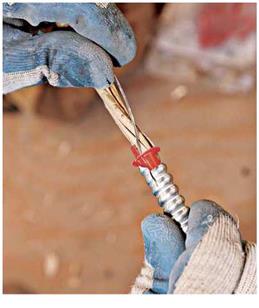

Rough cut lengths of cable about 2 ft. longer than the distance from box to box, to allow for generous loops at turns. After you have removed the metal sheathing, rip free the Mylar® wrap between its outer sheathing and the insulated conductors inside (AC cable has kraft paper surrounding its wires). To prevent the severed sheathing from slicing the insulation of individual wires, insert a plastic or fiber anti-short bushing between the wires and the sheathing, as shown below right. Note: Anti-short bushings are not required when using UL-listed MC cable clamps, but they are required by code (and manufacturers) for AC cable.

|

Roto-Split cutters cut through armored cable sheathing quickly and cleanly, without damaging the insulation of individual wires inside. |

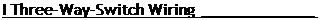

Here’s a representative three-way setup (there are many possible configurations). Whenever you use a white wire as a switch leg, tape it black to indicate that it’s hot. Here, all boxes are nonmetallic.

Once you’ve inserted the bushing, attach an appropriate cable connector to the end of the sheathing; most connectors employ a locknut that holds the threaded connector to a metal box. (Pull the BX bonding wire outside the sheathing and wrap it once around the connector screw; the bonding wire doesn’t go into the box.) After the cable connector is secured to the metal box, snip incoming wires so they are roughly 8 in. long. Splice and attach them to devices, as you would wires in nonmetallic cable

Because metal cable is flexible, support it every 6 ft. along its run and within 1 ft. of box connections. Staples should be snug but should not crimp the sheathing. The most common method of attaching cable is stapling it to the undersides or sides of joists where the cable runs parallel. When the cable runs perpendicular to framing, drill 58-in. holes through the center of the studs or joists and feed the cable through.

Note: Flexible metal cable can be punctured by drywall screws, so keep the cable back at least 114 in. from stud or joist edges. Otherwise, use steel nail-protection plates to safeguard the cable.

There are several types of conduit, including thin-walled electrical metal tubing (EMT), rigid metal conduit (RMC), flexible metal conduit (FMC), and rigid nonmetallic conduit (RNC), which is made of PVC plastic. With metal conduit, the conduit pipe is the equipment ground. Fittings are specific to each type of conduit and may vary further if the conduit is to be used underground or in high-moisture areas. Most types approved for exterior use will have weatherproof compression fittings. All conduit boxes must also be gasketed to keep moisture out.

Because conduit comes without wires inside, you must pull wire through it. Although wire can usually be pushed easily through straight lengths of conduit 10 ft. or less, use fish tape to pull wires around bends or through longer lengths.

First, use a conduit whose diameter is large enough for the number of wires you need to pull: 52-in. interior diameter (I. D.) conduit will suffice for most runs of 12AWG wire; use 54-in. I. D. conduit for the heavier wires, such as 8AWG or 6AWG wire, needed for stoves and such. Check your local code requirements. Using pulling compound (also called pulling lube) will make the task easier, as will having one person to feed wire and one to pull. THHN wire, whose coating is especially slick, is often specified when pulling is necessary. To keep wires from pulling off the fish tape, bend them tightly over the end of the tape, and wrap well with electrical tape.

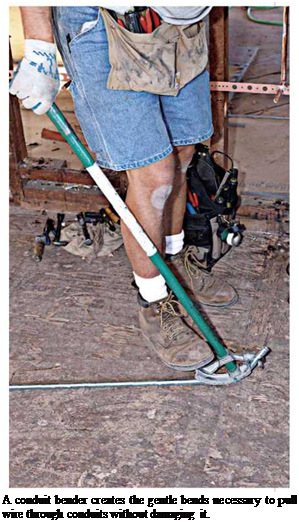

Pull wire only after you’ve attached conduit to boxes. If conduit bends more than the equivalent of four 90° bends between two boxes, you’ll need a pull box in the middle of the run, through which wires can be pulled. Too many bends creates too much friction to overcome and can stress the wire too much. Such boxes give you access to the middle of the run. To shape bends, use a conduit bender, which slides over the conduit. Bend the conduit, pushing down heavily on the shoe and bend till you achieve the desired curve: For 52-in. EMT conduit, a radius of about 552 in. is usual for a 90° bend. The bender will have arrows that indicate turning radiuses. Use a hacksaw to cut metal conduit; then use a debur – ring tool to smooth the cut ends and remove any metal spurs that could nick the conductor insulation.

Support EMT conduit at least every 10 ft. and within 3 ft. of termination. Connections within boxes are essentially the same as those for Romex cable, the principal difference being that

![]()

the conduit itself, because it is metal, provides the grounding. To ground individual outlets, run a grounding pigtail from the grounding screw on the device to the metal box.

Leave a reply