Tool Talk TOOLS FOR VINYL SIDING

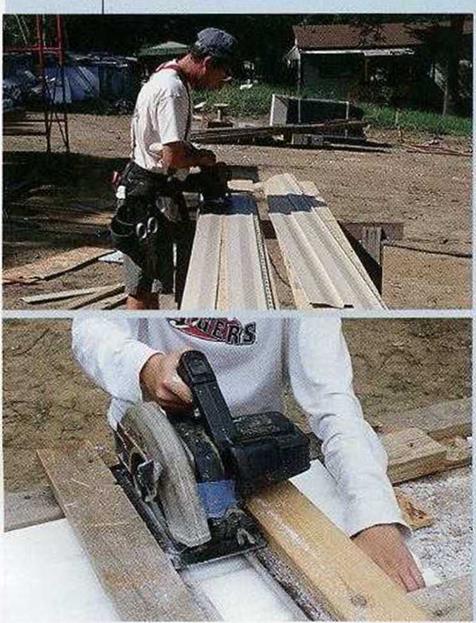

A LONG, FLAT work surface is essential for vinyl siding and sheet-metal work. A couple of 2×12 boards on sawhorses work fine. For precise 90-degree-angle cuts and angled rake cuts, I suggest making a cutting jig for a circular saw (see the photo at bottom left). The jig, which sits on a long worktable, is essentially a wooden cradle that guides the base of the circular saw. The cradle can be positioned at a right angle, or at

A LONG, FLAT work surface is essential for vinyl siding and sheet-metal work. A couple of 2×12 boards on sawhorses work fine. For precise 90-degree-angle cuts and angled rake cuts, I suggest making a cutting jig for a circular saw (see the photo at bottom left). The jig, which sits on a long worktable, is essentially a wooden cradle that guides the base of the circular saw. The cradle can be positioned at a right angle, or at

other angles, to the siding.

other angles, to the siding.

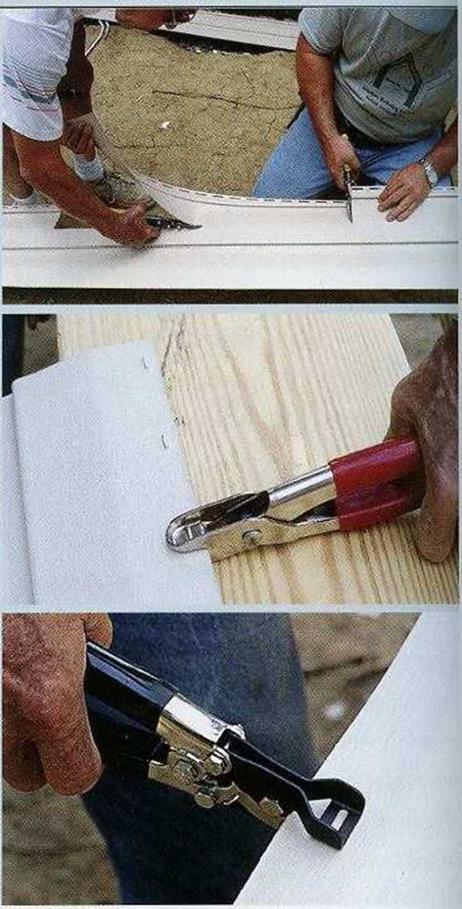

Use both right – and left-handed aviation snips to make straight and curved cutouts (see the photo at top right); tinsnips are also helpful. Other specialty tools you’ll need include a slot-punch, to make nailing slots in siding (see the photo at center right); a snap-lock punch, to create crimps or tabs that lock into the finish trim (see the photo at bottom right); and a zip tool, in case you need to remove a damaged panel from a wall.

the siding. Its also smart to check with builders in your area for any local wisdom. This is the best way to avoid the bulges, buckles, and tears that can result from incorrect installation. Most vinyl siding should not be nailed firmly against sheathing. The installation slots in the siding, starter strips, and other vinyl components are there for a reason. Keep the nail heads proud of the vinyl so that the vinyl can move.

The tools you need to install vinyl siding are mostly tools you probably already own, but there are a few others you’ll need to either buy or make (see the sidebar above). These tools are also handy for the sheet-metal work we’ll tackle later in the chapter.

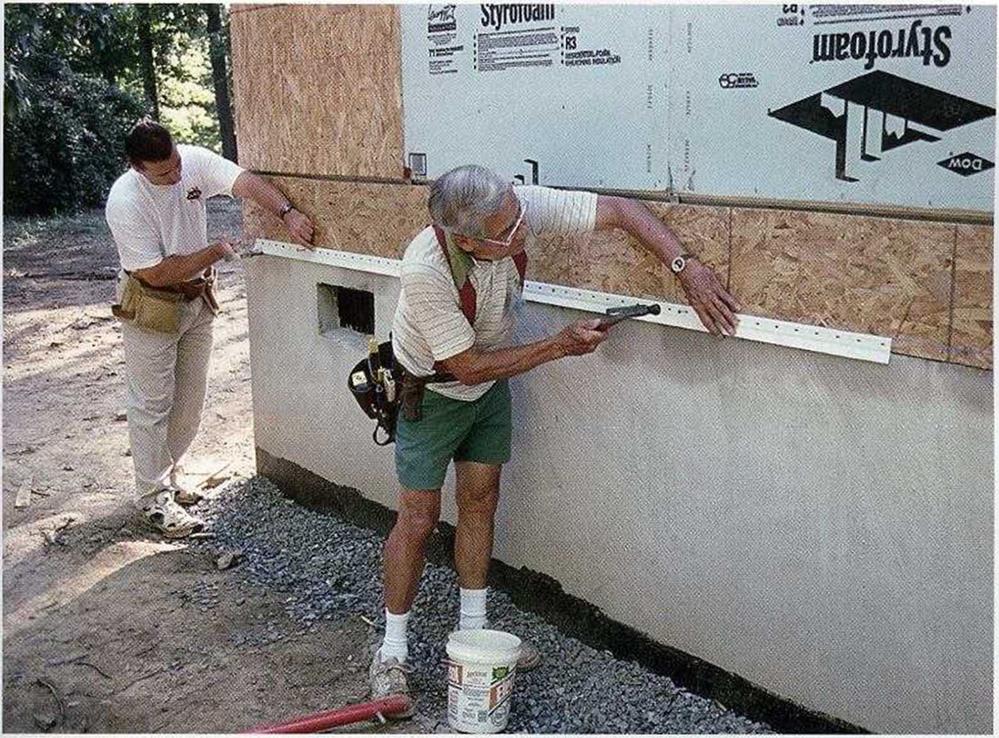

The installation of vinyl siding begins with different trim elements: starter strips, inside corners, outside corners, J-channel, and so on. The various trim details are designed to hide or interlock with siding ends and edges (see the illustration on p. 159). As with other homebuilding phases, if you get started right, the next steps follow more smoothly. The critical first step is to put on a straight and level starter strip right above the top of the concrete foundation wall or slab (see the top photo on the facing page). This strip can usually be installed by nailing through the sheathing and into the bottom of the mudsill or sole plate. The strip’s bottom edge can then extend about 1 in. over the concrete.

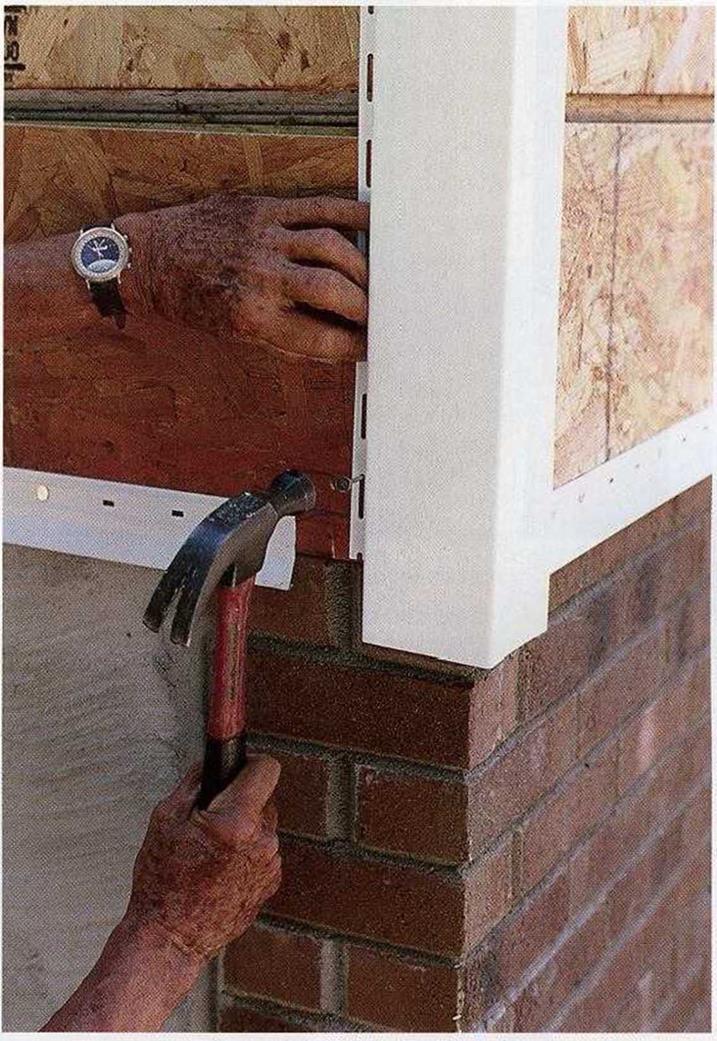

INSTALL VINYL TRIM. Attached along edges and corners, vinyl molding helps secure siding panels and contributes to a nice, finished appearance. Starter strips are installed along the bottom edge of the wall (left). To allow for heat-induced expansion, the end of a starter strip should be at least 1 in. away from the outside corner trim (below).

INSTALL VINYL TRIM. Attached along edges and corners, vinyl molding helps secure siding panels and contributes to a nice, finished appearance. Starter strips are installed along the bottom edge of the wall (left). To allow for heat-induced expansion, the end of a starter strip should be at least 1 in. away from the outside corner trim (below).

If the house is covered with housewrap, it is not always easy to see where to nail the starter strip. One way to establish the exact height of the strip is to measure down from the underside of the joist chords on the roof trusses and mark the proper height at various points around the house. This will ensure that the starter strip is level and equidistant from the top plates. Connect these points with a chalkline all around the house. On long walls, keep the line from sagging in the middle by having someone hold the line to a height mark near the middle of the wall, then snap the chalkline from the center to both corners.

To secure the starter strip, drive nails in the center of the installation slots, spacing them every 12 in. to 14 in. Leave at least / in. to ‘/ in. of expansion room between sections of starter strip as you install it around the building, and drive your first nail in each piece no less than 4 in. from an end. Remember: The strip must be able to move beneath the nail heads. At a walls outside corner, the starter strip must be 1 in. or more from the vinyl corner trim, as shown in the photo at right. Keep the strip

I. in. to 2 in. from the inside corners.

Leave a reply