Raise exterior through walls first

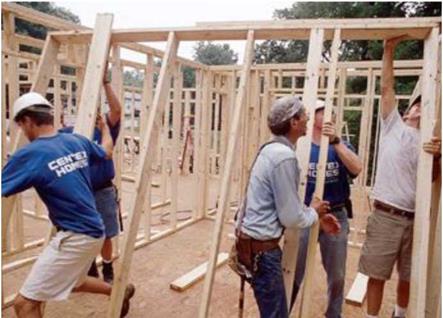

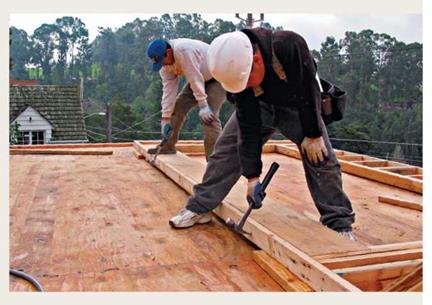

Start with one of the exterior through walls. Make sure there is no debris beneath the plates before raising the walls upright. If the wall is flat on the deck, stick the claw of a hammer into the double top plate, lift the wall up a bit, and put a 2x block under the wall. This way you can get your fingers under the wall to lift it. Keeping your back straight, use your legs to lift the wall to your waist, then take it overhead using your arms and upper body. Continue to raise the wall by pushing on the studs until it is fully upright. Once the wall is upright, hold

Remember that diagonal braces are important. Both exterior through walls are up; diagonal braces hold them securely while the other walls are raised. Use these temporary braces liberally where needed.

|

it steady—especi...

read more

But if you’re raising a partition in...

But if you’re raising a partition in...