Sampling of Groundwater

Groundwater sampling can be performed in existing facilities (wells, piezometers, springs, etc.) or in new ones that need to be built. In this latter case, it is more frequent to install piezometers of a small diameter, just enough to be compatible with the monitoring equipment to be subsequently used. Most groundwater sampling installations must be located downgradient to the road discharges in terms of the local groundwater flow if they are to look for road-induced contamination. A few upstream locations may also be chosen to allow a reference water condition to be established. Their depth should be at least 2-3 m below the minimum annual groundwater level in order to avoid having a dry piezometer. The necessary number of piezometers depends on the dynamics of groundwater (i. e...

read more

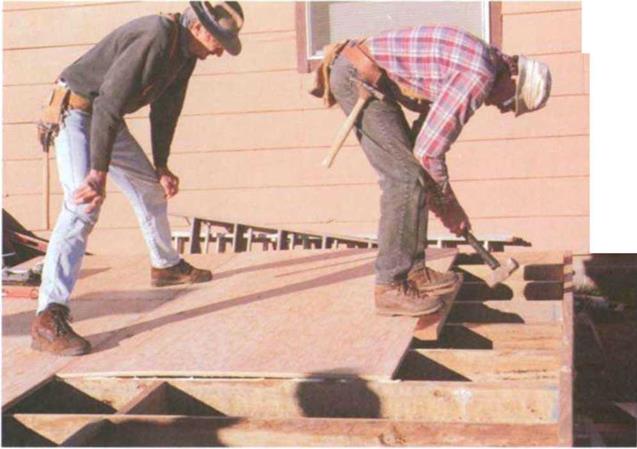

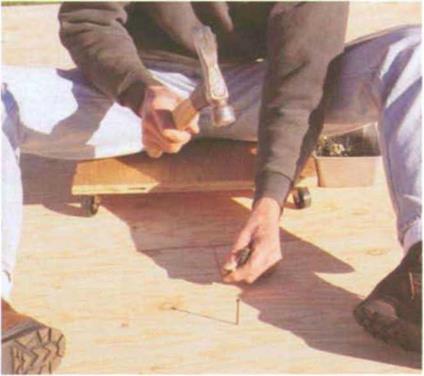

A nail buggy is a good tool when you have to nail subfloor by hand. Better to nail sitting on your bottom than crawling on your knees. Cut a 20-in. circle or square from 3A-in. plywood. Buy three or four good wheels at least 2 in. in diameter and screw them to the bottom of the plywood. Attach a bread pan to the side to hold nails. Now, like an Olympic swimmer doing laps, you can sit on the buggy and push yourself backward as you nail down subfloor. Just don’t roll off the edge of the floor.

A nail buggy is a good tool when you have to nail subfloor by hand. Better to nail sitting on your bottom than crawling on your knees. Cut a 20-in. circle or square from 3A-in. plywood. Buy three or four good wheels at least 2 in. in diameter and screw them to the bottom of the plywood. Attach a bread pan to the side to hold nails. Now, like an Olympic swimmer doing laps, you can sit on the buggy and push yourself backward as you nail down subfloor. Just don’t roll off the edge of the floor.