Author Testimonials

Paula Baker-Laporte

If someone had told me in the early years of my career that I would be writing a technical “how to” book about healthy homes, I would have looked at them with total incredulity! I would have explained that, as an architect, my main concerns were with the creation of beautiful and interactive spatial forms and that my aspirations were artistic rather than technical. It seems that fate had a different course for me. I joined the ranks of the chemically sensitive.

In retrospect, the roots of my illness can be traced back to formaldehyde overexposure that I suffered when for a short period I lived in a brand-new mobile home...

read more

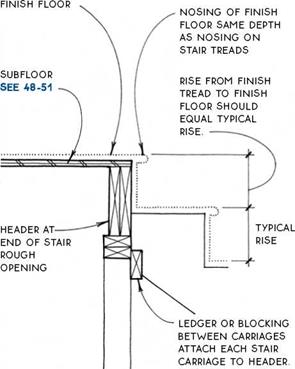

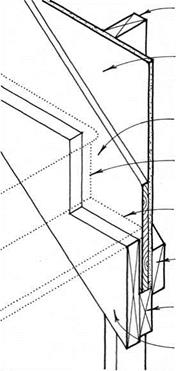

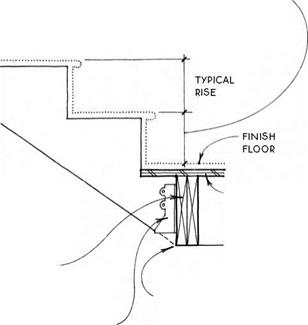

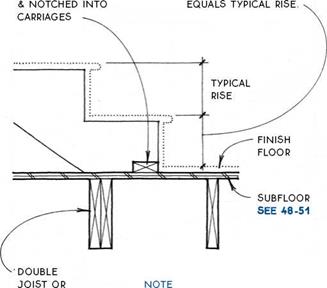

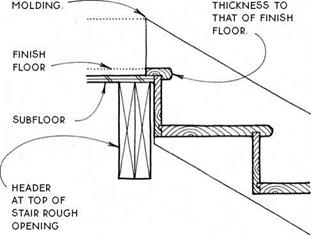

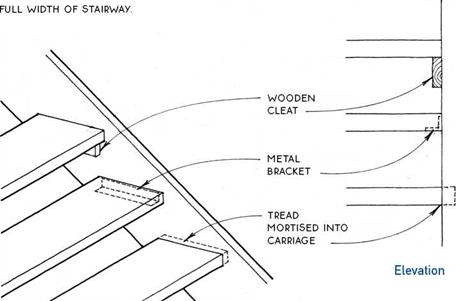

HOuSED STRINGER OF pREFABRicATED STAIR

HOuSED STRINGER OF pREFABRicATED STAIR

screwed TO Structural cARRIAGE;

screwed TO Structural cARRIAGE;