The Radioactive Countertop

John Banta was called to the home of a woman who was employed as a cook by the television industry. Her task was to create samples of the same recipe in various stages of preparation, from raw ingredients to oven-ready mixtures to finished product. The prepared foods were then delivered to the television studio so a celebrity on a culinary arts program could demonstrate the recipe.

During the investigation, John discovered that his client was being exposed to an unexpected occupational hazard. The orange-colored tile used for her counter was glazed with uranium

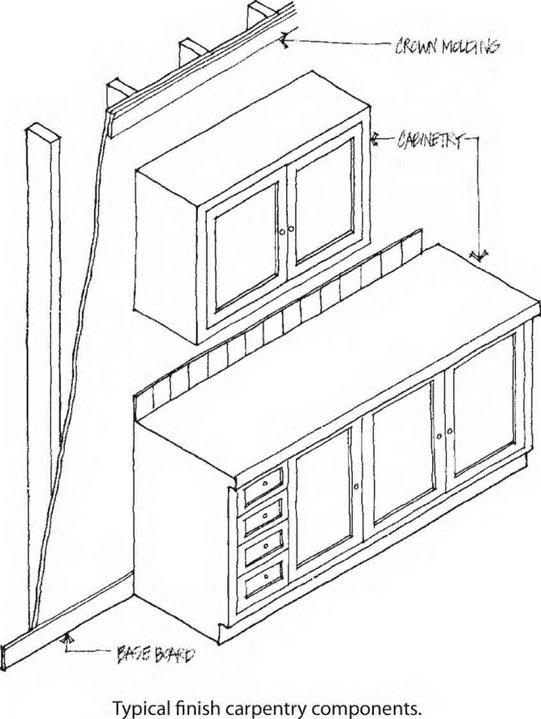

products for interior finishes and cabinetry (see Resource List for products)

• Medex or Medite II: A medium density fi – berboard manufactured without formaldehyde

. Multi – core: A low-emissions plywood with a variety of hardwood veneers

• PureKor: Specify their formaldehyde-free board

• Roseburg SkyBlend Particleboard: Scientific Certification Systems certified, low emissions, certified recycled content, no urea-formaldehyde added during manufacturing process

• Temstock-Free: No added urea-formaldehyde particleboard underlayment and industrial-grade particleboard

• Terramica: Scientific Certification Systems certified no added urea-formaldehyde particleboard underlayment and industrial-grade particleboard

• Tru-Spec: Line ofurea-formaldehyde-free, millwork-quality wood strand engineered

oxide, a highly radioactive substance that was making the numbers on the Geiger counter spin too fast to count. For over 30 years this woman had worked at a radioactive counter, slicing, dicing, mixing, and arranging her creations.

When she learned of the radioactivity, the client revealed to John that she had recently had a precancerous lesion removed from her intestines. Her surgical scar was located at the level where the counter pressed against her while she cooked. The client was advised to have her countertop replaced. Her physician concurred.

wood products for interior wood finishes and cabinetry, GreenGuard certified

Because hardwoods take a long time to grow and are therefore not as sustainable as faster growing alternatives, you might consider the following healthy alternatives to hardwood for your finsh carpentry and cabinetry:

• Alio wood: Hardwood lumber substitute manufactured from faster growing softwoods and agri-based materials

• Environ Biocomposites: Line of formaldehyde-free, agri-based sustainable panel products for interior finishes and cabinetry

• Bamboo: Refer to Division 9 for bamboo sources

The ideal countertop material for a healthy home would have a solid, nonporous surface that is stain – and scratch-proof. It could be attached by mechanical means directly to the cabinet boxes, thus avoiding the need for un- derlayment and adhesives. It would be beautiful, inexpensive, and manufactured in a variety of colors. Unfortunately, all of these characteristics are not found in combination in a single countertop option. Chart 6.1 reviews the most common countertop materials and outlines specification concerns for each.

Chart 6.1: Countertop Comparisons

|

Type |

Relative cost |

Advantages |

Disadvantages |

Comments |

Specify |

|

High pressure laminates (e. g., Formica, Wilson art) |

Lowest initial investment |

•Wide variety of colors, patterns, textures, and sheens • Low cost • Seamless surface |

• Glued to particleboard with toxic glues • Particleboard outgasses formaldehyde • Not stain – or acid – resistant • Will scratch • Cannot be resurfaced • Short life; deteriorates quickly if the particleboard gets wet |

• Not a good choice for a healthy home |

• Fasten to cabinetry with mechanical fasteners • Seal all exposed edges and surfaces of particleboard with foil or one of the vapor barrier sealants listed in Division 9 |

|

Solid-surface materials (e. g., Corian, Avonite, Swanstone, acrylic or plastic colored with resin) |

Expensive |

■ Nonporous • Sanitary; integral sinks and rolled backsplashes are easy to clean • No substrate needed for most • Scratches and stains are easily sanded • Attractive marble – and granite-like surfaces • Can be mechanically fastened |

* Can be more expensive than granite or marble |

• Select a type that does not require substrate |

• Fasten to cabinetry with mechanical fasteners |

|

Type |

Relative cost |

Advantages |

Disadvantages |

Comments |

Specify |

|

Tile |

Can be moderate |

• Hard, scratch – resistant surfaces • Large variety of sizes, colors, and textures to choose from |

• Grout joints are subject to staining and mold and bacterial growth • Glazes may contain heavy metals or be radioactive •Tiles can crack or chip under heavy impact |

• Choose large tiles to reduce the number of grout joints • Choose presealed tiles • Choose commercially rated tiles • Choose tiles requiring the narrowest grout joints • Choosing porcelains with integral color will disguise chips |

• Follow recommendations in the tile section of Division 9 for underlayment, tile setting, and grout sealing |

|

Butcher block |

Moderate |

• Warm, inviting aesthetics • Natural material • Can be refinished by sanding • Does not require underlayment • Can be mechanically fastened |

• Porous surface stains easily and can harbor mold growth |

• Seams might have been glued with formaldehyde – based adhesives |

• Finish with odorless, nontoxic oil such as walnut oil ■ Fasten to cabinetry with mechanical fasteners • Use adhesives that are solvent – and formaldehyde-free |

|

Solid sheet granite |

Expensive |

• Wide selection of very beautiful stones • Hard, scratchproof, stain-resistant surface that will last forever • Solid, seamless surface • Can be mechanically fastened or glued with silicone • May not require substrate |

• May be cost prohibitive • Surface must be finished with impregnating finish |

• Oil or butter left on surface will stain it • Must check for radioactivity |

■ Examine MSDS of surface impregnating finish for toxicity • Fasten mechanically or with 100% pure silicone caulk (aquarium/food grade) |

|

Engineered stone quartz — 93% quartz, 7% resin (e. g., Sile – stone, Caesar – Stone, Cambria, Zodiaq) |

Expensive |

• Does not require sealing • Stain-, scratch-, and heat-resistant • Hygienic • Can be mechanically fastened |

* Heavy • Requires professional installation |

• Good choice for durability and hygienic properties and because it does not require use of impregnating finish |

– Fasten mechanically |

|

Type |

Relative cost |

Advantages |

Disadvantages |

Comments |

Specify |

|

Granite tile |

Moderate |

• Can resemble granite but is less expensive than slab • Very thin grout joints can be sealed with transparent silicone • Mar- and scratch – resistant |

• Requires epoxytype glues to set • Requires underlay – ment |

• Oil or butter left on surface will stain it • Must check for radioactivity |

• Examine MSDS of surface impregnating finish for toxicity • Refer to section on underlaymentfor tile in Division 9 |

|

Stainless steel |

Expensive |

• Nonporous, nonstaining • Easily cleaned continuous surface |

•Thinner gauges require underlay – ment • Noisy • Must be special – ordered |

* Conducts electricity • Proper ground fault interrupters are essential to prevent potential electrocution |

• Use formaldehyde – free underlayment and mechanical fastening |

|

Solid slate |

Comparable to granite |

• Nonporous, nonstaining |

• Softer than granite and can chip |

• Can be mechanically fastened • Does not require finish |

composites are used in many finish applications including cabinetry, molding, shelving, and trim. They should not be used in a healthy home. The following maybe specified:

composites are used in many finish applications including cabinetry, molding, shelving, and trim. They should not be used in a healthy home. The following maybe specified: