Water-Induced Damage in Asphaltic Wearing Surfaces

5.5.1 Introduction: The Problem of Water for Road Surfacings

Practice has shown that asphaltic wearing surfaces which are exposed to water generally start losing aggregates prematurely through a damage phenomenon that has become known as asphaltic ‘stripping’ or ‘ravelling’. Stripping is generally attributed to water infiltration into the asphaltic mixture, causing a weakening of the mastic, and a weakening of the aggregate-mastic bond. Due to the continuing action of water and traffic loading, progressive dislodgement of the aggregates can occur. This initial stripping rapidly progresses into a more severe ravelling of the wearing surface, and ultimately leads to pothole forming, Fig. 5.4.

Sometimes, open-graded mixtures are deliberately designed and laid. As described in Section 5.7, this is to help drain pavement surface water. This tends to

|

Fig. 5.4 Water-induced damage in asphaltic material (a) ravelling (b) potholing (de Bondt, 2005). Reproduced by permission of N. Kringos |

allow water to reside more or less permanently within the mixture, contributing to the development of water-induced damage.

An additional challenge in the pavement industry is that there is often a big difference between the asphaltic mixture composition and the material characteristics, which are determined in the laboratory, and the asphaltic mixture which is actually constructed on the road. For instance, with regards to water-induced damage, it is not uncommon for the asphaltic mixture components to be exposed to water, even before construction, Fig. 5.5. Since most aggregates and binders do absorb moisture, when exposed to a wet environment, a binder with a significantly reduced stiffness and an initially damaged mixture would end up on the pavement – see Fig. 5.6.

The only real solution to date, for keeping the asphaltic wearing surfaces at an acceptable performance and safety standard, is frequent closure of the major highways for repair and maintenance, implying high costs and frequent road congestion.

|

Fig. 5.5 Wet asphaltic mixture components before construction (Huber, 2005). Reproduced by permission of N. Kringos |

|

|

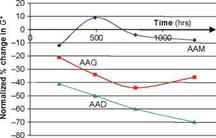

Fig. 5.6 (a) water absorption in three SHRP binders (b) reduction of binder stiffness, G*, due to water infiltration (Huber, 2005). Reproduced by permission of N. Kringos

For this reason, it is greatly desired to shift the solution from a repair measure to a preventive measure. This is currently impossible as mixture designers have no prior knowledge of the engineering properties of the mixture at the time of purchase of the bulk materials. Common practice for evaluation of the moisture sensitivity of any particular asphaltic mixture is to perform a set of mechanical tests on dry and moisture-conditioned specimens, giving ‘moisture sensitivity ratios’ for the engineering mixture properties. Unfortunately, such ratios can only be used to compare case-specific mixtures under a set of pre-determined conditions, but give no insight into the actual water damage phenomena, nor lead to any fundamental remedies.

For this reason, in recent years, these phenomenological studies are giving way to more fundamental studies in which both experimental and analytical investigations on water-induced damage in asphaltic mixtures are combined. Researchers at Delft University of Technology in the Netherlands have focussed on developing a computational tool which allows a study of the interaction between physical and mechanical water damage inducing processes. The tool developed is named RoAM (Kringos & Scarpas, 2004; Kringos, 2007) and operates as a sub-system of the finite element system developed at TU Delft, CAPA-3D (Scarpas, 2005).

Leave a reply