Thermal Conductivity Sensors

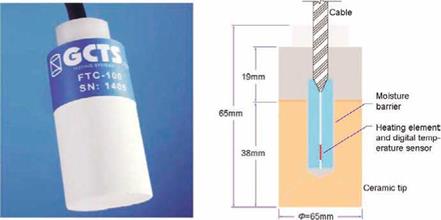

Thermal conductivity sensors (TCS) are used to indirectly relate matric suction to the thermal conductivity of a porous medium embedded in a mass of unsaturated soil. Any change in the soil suction results in a corresponding change in the water content of the porous medium (governed by its characteristic curve). The thermal conductivity of a rigid porous medium is a direct function of the water content. Therefore, if the thermal conductivity of the porous medium is measured, the matric suction of the soil may be indirectly determined by correlation with a predetermined calibration curve. Figure 3.14 shows the main components of a modern commercial TCS.

|

Fig. 3.14 Picture and schema of a thermal conductivity matric suction sensor (TCS). Reproduced with permission from GCTS Testing Services |

Some disadvantages usually imputed to the old-fashioned TCS included the problems associated with drift, and, for many sensors, deterioration in the sensor body over time, as well as uncertainties concerning the drying and rewetting processes due to hysteretic effects in the sensor calibration. But most of these problems have been resolved. The major advantages of the more recent TCS include the relative ease with which the sensors may be set up for automated data acquisition, their relatively low cost and their present capability to measure matric suction over a wide range (0-1200 kPa). Figure 3.15 shows some laboratory soil suction measurements carried out with both tensiometers and TCS, where tensiometer failures due to cavitation were noticeable. For further details regarding TCS see Rahardjo & Leong (2006).

Leave a reply