Development of the water mill in the Roman Empire

About fifty years after Vitruvius, under the reign of Vespasian and Titus, Pliny the Elder[255] wrote in his book, The Natural History:

“All the grains are not easily broken. [….] Throughout the greater part of Italy, however, they employ a pestle that is only rough at the end, and wheels turned by water, by means of which the corn is gradually ground.”[256]

The Roman development of the water mill has been consistently underestimated; but new archaeological findings are becoming more and more numerous.[257] One can find remains of simple mills on small rivers near Hadrian’s Wall at the Scottish border.[258] In eastern Tunisia, at Chemtou (the Roman Simitthus) the remains of an installation comprising three horizontal wheels set side by side have been found near a dam constructed by Trajan on the river Medjerda.[259] And in North Africa, there are still other horizontal – wheel mills. Vertical-wheel mills are found in Gaul from the 1st or 2nd centuries; in the villas ofVar in the 2nd century; on the Janiculum Hill at Rome from the 3rd century; and at the agora of Athens in the 5th century. There is a depiction of a noria on a mosaic dating from 469 AD at Apamea-on-Orontes; this date comes after the fall of the Roman Empire in the west, but the representation suggests that the use of the noria had largely spread to the east during the Roman period. And then, there is the flour mill of Barbegal.

Let’s now describe this installation,[260] the one we used to begin our discussion of

|

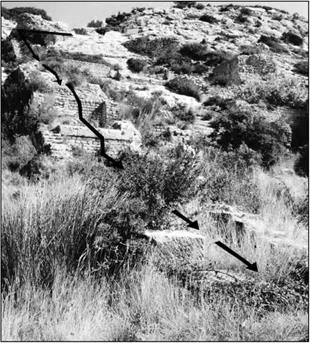

Figure 6.22 Roman flour mill at Barbegal: view from the summit of the rock outcrop where the aqueduct arrives; to the left and the right, in the form of a V, one can see the two walls that carried the two divergent lateral canals. These canals delivered water to the two “mill” canals that, in turn, cascaded down the slope and supplied the two banks of water wheels (photo by the author). |

|

|

Roman mills. We have seen that the aqueduct that is dedicated to the supply of the flour mill lies parallel, in its final stretch, to the aqueduct that supplies the city of Arles. Both aqueducts come out of a junction basin which is supplied, in its turn, by two canals delivering water from different remote sources.

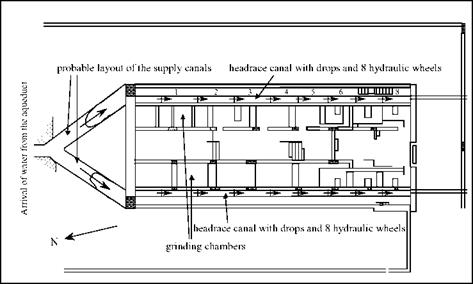

At the mill, another distribution basin[261] conveys water into two parallel headrace canals that descend from the hill with a discharge that modern studies have estimated at about 0.15 m3/sec. Along each of these canals, eight vertical wheels, each about 2 m in diameter, are aligned from the top to the bottom of the slope. Each wheel has a sill or weir immediately downstream of it, controlling flow into a small drop that feeds water onto the wheel below it. Adjacent to each wheel, near its center, is a chamber enclosing the reduction gears, with grinding wheels likely set on a platform above each of these chambers.

One of the astonishingly modern aspects of this installation is its engineered, non-natural water supply, using one of the two branches that earlier had come together to supply Arles. The mill was built at a very convenient location, benefiting from a steep slope and yet providing ready access from the plain below, obviating the need for the installation to accommodate the vagaries of a natural river. The discharge is regular, with no risk of erosion. This installation probably dates from the beginning of the 2nd century AD.[262]

|

Figure 6.24 Reconstitution of the plan of the flour mill of Barbegal (after Sellin, 1979). The light lines indicate assumed structures. |

Leave a reply