Wind Can be a Serious Problem

|

|

![]()

In certain areas of the country like the southern U. S. Gulf Coast, Hawaii, “Tornado Alley,” coastal Alaska, and other areas, code demands a more positive tie-down mechanism than the positioning pin and gravity technique that I employ in northern New York. Fortunately, several manufacturers make a variety of anchoring fasteners whose purpose is to tie the base of the posts to foundations. Three companies are listed in Appendix C. One of the leaders in the field is Simpson Strong-Tie Co., Inc. In their High-Wind-Resistant Construction Product Selection Guide (catalog C-HW02, November 1, 2002), on page 4, they say: “Newer building codes such as the International Building Code (IBC), the International Residential Code (IRC), and the Florida Building Code (FBC),

In certain areas of the country like the southern U. S. Gulf Coast, Hawaii, “Tornado Alley,” coastal Alaska, and other areas, code demands a more positive tie-down mechanism than the positioning pin and gravity technique that I employ in northern New York. Fortunately, several manufacturers make a variety of anchoring fasteners whose purpose is to tie the base of the posts to foundations. Three companies are listed in Appendix C. One of the leaders in the field is Simpson Strong-Tie Co., Inc. In their High-Wind-Resistant Construction Product Selection Guide (catalog C-HW02, November 1, 2002), on page 4, they say: “Newer building codes such as the International Building Code (IBC), the International Residential Code (IRC), and the Florida Building Code (FBC),

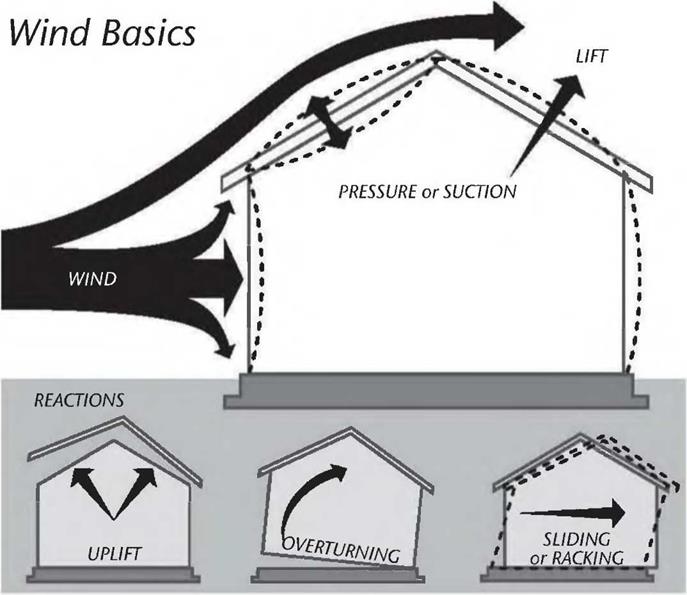

have had a profound effect on the way wind design is performed/’ The same publication gives this concise overview of how strong winds affect buildings: During a thunderstorm, blizzard, hurricane, or tornado, the force of the wind on a house works in three ways:

have had a profound effect on the way wind design is performed/’ The same publication gives this concise overview of how strong winds affect buildings: During a thunderstorm, blizzard, hurricane, or tornado, the force of the wind on a house works in three ways:

1. As it flows over the roof the wind creates a strong lifting effect (uplift).

2. It exerts horizontal pressure which tries to overturn the structure.

3. If overturning is resisted, the wind pressure tries to slide the structure off of the foundation or to rack the walls.

Be extremely careful working around or under heavy timbers that have not yet been firmly tied to each other and diagonally braced to the ground, foundation, or floor. Avoid timber framing on windy days.

Tying Posts and Sills to the Foundation

While codes in areas of severe wind potential are concerned with all the structural components, up to and including tying roof trusses and rafters down to the

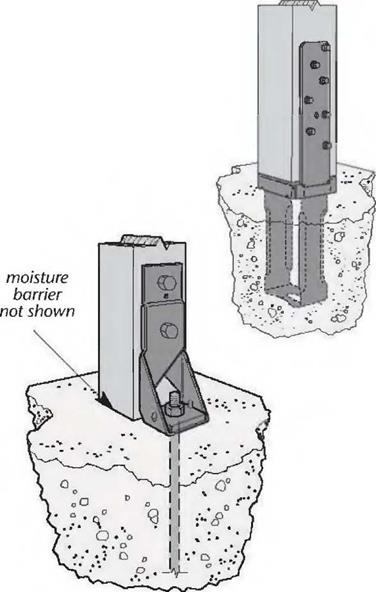

top plate, the first building requirement will be to tie the posts to the foundation. Simpson makes a variety of post and column bases for the purpose, and some examples are shown in Fig. 4.17, reprinted by kind permission from Simpson. Other companies make similar products. Note that some of these post bases can be fastened to anchor bolts set in the concrete (or in grouted concrete block cores), while others involve embedding the lower part of the base into the concrete. With a poured slab or footing, these anchors will have to be installed accurately at the time of the pour. Make sure that you understand how the base works before you set it up in the concrete, and be careful that the part upon which the post rests is flush with the top of the

foundation or a tiny bit above it. An advantage of the fastener styles that make use of anchor bolts or pins is that the base-support piece is snugged up to the foundation by tightening a hexheaded nut. This system seems a little more forgiving of error.

While visiting Hawaii’s Big Island in 2003, I noticed that a lot of people make use of tie-down connectors from the foundation right through to the roof. The Simpson Strong-Tie folks call this a “continuous load transfer path.” Steve Sugar says that his building inspector is quite insistent on that, because Hawaii can bare the brunt of some pretty powerful winds. Steve and Eileen Sugar’s house, seen in Fig. 4.18, is built up on twenty or so four-by-four posts, each married to heavy concrete bases as shown in Fig. 4.1 at the beginning of the chapter. The metal fasteners were cast in place. The living area is all above the garage space, a protection in case of flooding (in a region of 200-plus inches (5.08 meters) of rain per year) or tsunami (tidal waves) that occasionally hit the coast.

While visiting Hawaii’s Big Island in 2003, I noticed that a lot of people make use of tie-down connectors from the foundation right through to the roof. The Simpson Strong-Tie folks call this a “continuous load transfer path.” Steve Sugar says that his building inspector is quite insistent on that, because Hawaii can bare the brunt of some pretty powerful winds. Steve and Eileen Sugar’s house, seen in Fig. 4.18, is built up on twenty or so four-by-four posts, each married to heavy concrete bases as shown in Fig. 4.1 at the beginning of the chapter. The metal fasteners were cast in place. The living area is all above the garage space, a protection in case of flooding (in a region of 200-plus inches (5.08 meters) of rain per year) or tsunami (tidal waves) that occasionally hit the coast.

On the other side of Hawaii, Terry, another owner-builder, also put his living space eight feet up, and for similar reasons. A self-reliant mango farmer, Terry used strong homemade metal fasteners to tie his main girders to the seven-foot pillars made from concrete-filled hollow-core chimney

blocks. These blocks, which come in 16- by іб-inch (and other) sizes, are very handy for building a deck up off of the ground. Filling the blocks with concrete and vertical rebar makes a strong pillar, and the U-shaped plate assembly can be set into the concrete of the last core. We see just the exposed part of this assembly in Fig. 4.19. Note, also, that the girder is tied to the main corner post column with a strong metal strap.

We’ll return to Hawaii later to see how floor girders and roof rafters were fastened down to posts.

We’ll return to Hawaii later to see how floor girders and roof rafters were fastened down to posts.

Specialty fasteners are also available for tying sill plates down to foundations, although regular anchor bolts, as already described, are very strong. In high-wind areas, your tie-down methods will have to agree with local code or the local codeenforcement officer, who may have some discretion. Although Timber Framing for the Rest of Us is concerned with post-and-beam framing, not conventional balloon framing, Fig. 4.20 may be of interest to show that fasteners are available for virtually every kind of wood-to-wood (or wood-to-masonry) situation.

Leave a reply