When Two Beams Meet Over a Post

Where any two beams meet over a post, there are many ways, short of matrimony, to join them together. Traditional timber framers have a variety of joints to use in this situation, including an assortment of “scarf” and “dovetail” joints — these take practice — and half-lap joints, as in Fig. 4.14. Lap joints are not too difficult to make with common tools, and you may like to have a go at them. A drawback, however, is that shear strength of the beam is diminished when it is cut half way through. In fact, weakening of structural members is almost always the case with any traditional joint. Another example of this would be an eight-by-eight-inch beam with a tenon of two-by-eight-inch cross-section carved into its end for insertion into the mortise of an adjacent post. Shear strength is reduced by 75 percent in this case. This is not a problem for timber framers because the structures are so extraordinarily over-built in the first place, and good tight-fitting joints and pegs go a long ways towards promoting strong joints.

The rest of us have several choices:

1. Truss plates on the top. I used this method to join the tops of the post-supported octagonal ring beam at Earthwood. This octagon, halfway between the center pillar and the external walls, cuts the floor joist spans in half on the first floor, and the roof rafter span in half on the second story. When you cut its span in half, you make a beam — remember? — four times stronger on bending. The truss plates are out of the way and out of view, so this was an effective solution. See Fig. 4.23.

2.

Toe-nailing or toe-screwing from the top of one horizontal timber, diagonally into the end of the adjacent member. Not quite as rigid as the truss plate

Toe-nailing or toe-screwing from the top of one horizontal timber, diagonally into the end of the adjacent member. Not quite as rigid as the truss plate

method, but quite strong just the same, and useful where truss plates will either be seen or be in the way of fastening another post or beam.

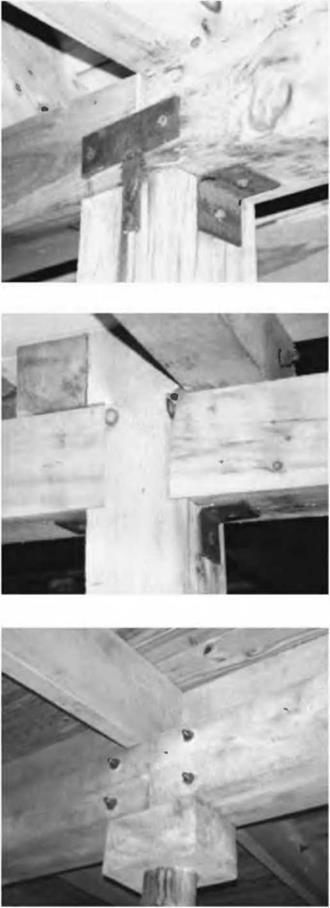

3. T-straps. (Figs. 4.13, 4.24 and 4.25) You can buy a variety of these at the building supply, and their esthetic qualities vary. My friend Steve in Hawaii used the off-the-shelf connectors shown in Fig. 4.24 to join two four-by-ten girders over a four-by-four post. This pair of connectors does everything in one shot: it connects the two girders, and connects the girders to the post. It is not beautiful, but the detail is down in the garage, under the living space, so esthetics matter less. Fsthetically, the best T – straps I have seen are homemade as shown in Fig. 4.13 and use lag screws instead of nails. Several acquaintances have made their own attractive T – straps from one-eighth-inch stock or better, and painted them black. Whenever this method is used, full strength comes from using them on both sides of the joint. Some manufacturers make decorative heavy strap connectors, too.

|

4.28.

Maintain a whole toolbox of these joining methods and have them all available for use as needed. Sometimes one method won’t work but another will. Redundancy of methods is not necessarily a bad thing, either. With large projects, in fact, good engineers deliberately incorporate structural redundancy into buildings to allow loads to be carried by more than one path.

Leave a reply