Timber from Small Sawmills

The wood descriptions above are general in nature. A particular species can exhibit varying characteristics depending on where it grows. A local sawyers advice is as valuable as the list above, particularly one who has many years of experience in the area.

Local sawyers charge for their lumber by the board foot. Logically, you would think that you’d get a break on price for an eight-by-eight over, say, four two-byeights or eight one-by-eights of the same length. After all, the board footage is the same in all cases, and the sawyer has far fewer cuts to make with an eight-by-eight. You should get a price break, right? Well, I’ve never seen that happen. You pay by the board foot, end of story. The only exception is that if you give your sawyer your complete timber schedule and ask him (or her, though I have yet to meet a female sawyer) to give you a cost for the whole job, the generic “he” will take things like this into consideration, especially if there are other mills in the area.

If possible, leave your timber schedule with at least three local sawmills for pricing. But also ask about how long it will take to finish the order and whether or not they can arrange for delivery. Most sawyers are too busy to deliver on their

own, but they often know someone with a truck who can deliver the timbers to you. You can also use your own pickup truck if you are not too far from the sawmill. Several loads will be required, and fresh-cut timbers are well, heavy. Length of timber is limited to around ten feet for pick-up transport, unless the truck is equipped with an overhead wood rack. I hauled all the timbers for our new addition at Earthwood (Chapter 5) in our Nissan pick-up, but it took a few loads, at 18 miles round trip.

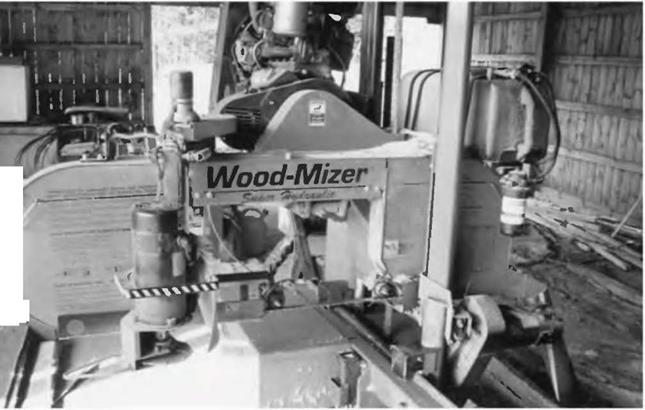

All sawyers think — or say — that they are accurate, and most are, but take a tape measure with you and quietly check out a few timbers that are already lying around. I work with two local sawyers. “Sawyer 1” has a bandsaw and “Sawyer 2” has a traditional large circular saw. Each one makes very regular dimensional timbers — I have never had a complaint about this — but Sawyer 1 sometimes lets some shoddy pieces go through: excessive wain, heart rot, large knots on the edge of the timber creating a weakness. The other guy doesn’t let this type of thing pass.

All sawyers think — or say — that they are accurate, and most are, but take a tape measure with you and quietly check out a few timbers that are already lying around. I work with two local sawyers. “Sawyer 1” has a bandsaw and “Sawyer 2” has a traditional large circular saw. Each one makes very regular dimensional timbers — I have never had a complaint about this — but Sawyer 1 sometimes lets some shoddy pieces go through: excessive wain, heart rot, large knots on the edge of the timber creating a weakness. The other guy doesn’t let this type of thing pass.

I usually end up going with Sawyer 2, even though he is a little more expensive, because of timber quality and the fact that he is reliable in having the job ready when he says it will be. Also, he will give me special attention for some of the personal quirky projects that we have going at Earthwood. Once, I needed a couple of six-by-eight posts resawn on an angle along their length. I showed up with the timbers, and he stopped production to accommodate me, and did a good job. Another time, he pulled five very cylindrical logs out of his pile for use as rollers at one of our megalithic stone workshops. This kind of service is beyond price.

Leave a reply